The colourants used in point-of-sale tinting systems must have excellent compatibility with different base paints to ensure consistent, reproducible colours. This remains one of the toughest challenges facing the waterborne architectural paint formulator today. This paper will describe the mechanisms involved in colourant stabilization and explain how specific surfactants can be used within the base paint formulation to prevent destabilization of the colourant, ensuring its intended performance.

Introduction

Point-of-Sale (POS) Tinting Systems: Benefits and Challenges

POS tinting systems allow paint manufacturers to produce only a few base paints into which colourants are added at the store. This approach enables customers to decorate with a very broad colour palette while paint manufacturers and retailers can save money by stocking fewer materials. As a result, much less unused paint goes to waste. However, the colorants used in POS tinting systems must have excellent compatibility with different base paints to ensure consistent, reproducible colours under all conditions.

Changes in the universal colourant compositions will often necessitate a reformulation of the base paints to compensate for any adverse effects the new colourants may have on final paint properties. including colour development and colourant acceptance.

Colour Development and Colourant Acceptance

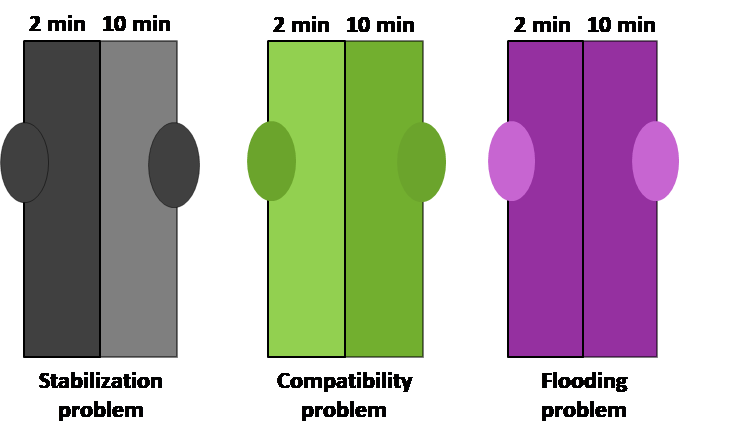

The term “colour development” describes the degree of tint strength and colour quality achieved when a paint is tinted. Good colour development implies that the colour has not changed and is of the expected colour strength. “Colourant acceptance” is the ability of a base paint to be tinted in a manner that enables consistently good colour development to be achieved uniformly throughout the applied coating. A practical method for determining the degree of colourant acceptance is the so-called “rub-out” test. Any colour differences can be readily detected on the “rub-out” and are indicative of destabilization of at least one of the pigments used in the formulation. Figure 1 shows examples of colourant acceptance issues.

Figure 1. Examples of typical colourant acceptance issues seen in “rub-outs”.

Figure 1. Examples of typical colourant acceptance issues seen in “rub-outs”.Surfactants: The Cause of and Potential Solution to the Problem

Surfactants are, the additives of choice for providing the wetting, dispersion and stabilization of the pigments and fillers used in waterborne coatings.

To better understand the behaviour of surfactants in coating formulations, a series of experiments was conducted to study the ability of various nonionic surfactants to improve colourant acceptance in waterborne architectural coatings.

Results and Discussion

Experimental

Commercial waterborne base paints were purchased from local retailers and used as received.

The acetylenic diol alkoxylates, formulated surfactants, and alcohol ethoxylates were evaluated in post-addition to the base paint at 1.0 wt%. The next day, 1.0 wt% of colourant was added to the base paint and the paint was shaken for two minutes. After two minutes, a small sample was removed for evaluation. The remaining paint was then mixed for a total mixing time of ten minutes.

Drawdowns of the “2 min” and “10 min” paint samples were made on a Leneta chart (150-micron wet film thickness), rub-out tests were performed one minute after drawdown.

To determine the influence of the additives on colour compatibility and colour strength, L*, a*, b*, c*, h* and DE* values were measured on the dried drawdowns.

Results

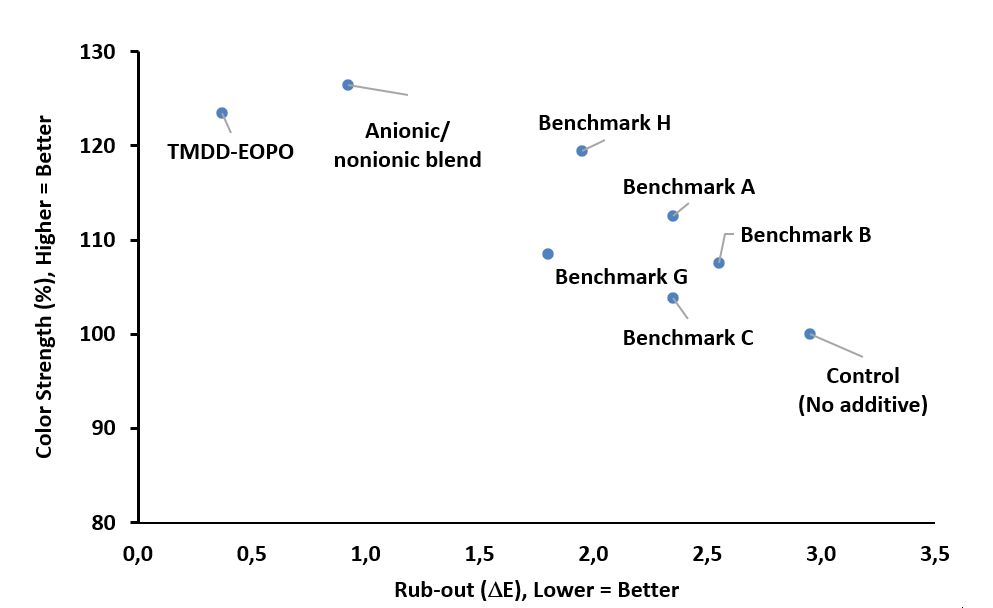

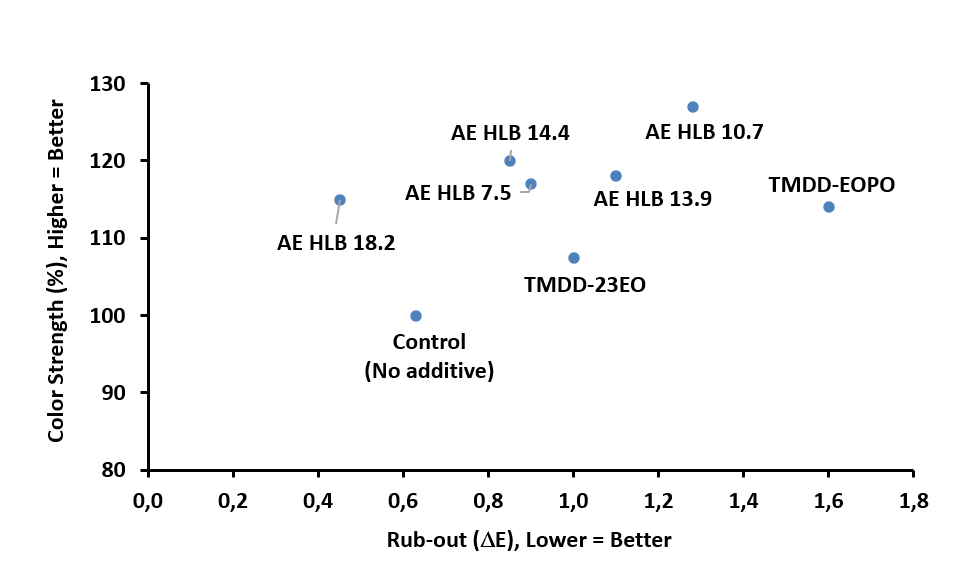

In a waterborne acrylic base paint that was tinted using 1.0 wt% of a pigment violet 23 colourant, it was observed that many surfactants of varying chemistries were able to slightly to significantly improve the colour strength of the paint; however, only the alkoxylated acetylenic diol (TMDD-EOPO) showed a significant improvement (DE < 0.5) in the rub-out test (Figure 2 and 3).

Figure 2. Comparison of colour strength and rub-out (E) values obtained for a 1.0 wt% PV23-tinted waterborne acrylic paint containing 1.0 wt% color acceptance additive.

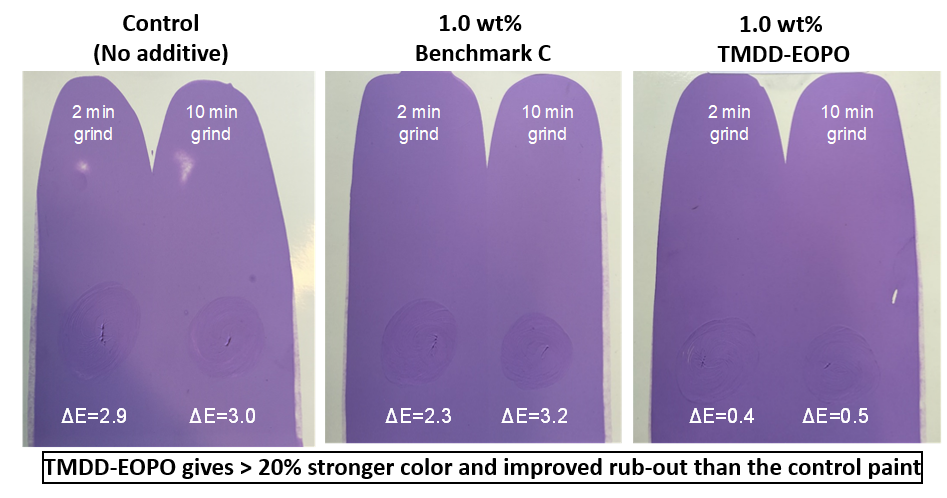

Figure 2. Comparison of colour strength and rub-out (E) values obtained for a 1.0 wt% PV23-tinted waterborne acrylic paint containing 1.0 wt% color acceptance additive. Figure 3. Addition of 1.0 wt% TMDD-EOPO significantly improves the colour acceptance of a waterborne acrylic paint when it is tinted with 1.0 wt% PV23 colourant.

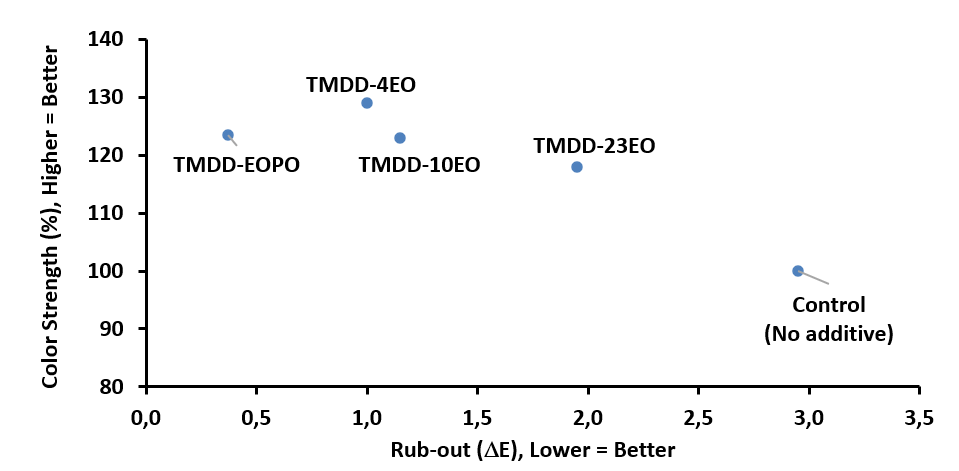

Figure 3. Addition of 1.0 wt% TMDD-EOPO significantly improves the colour acceptance of a waterborne acrylic paint when it is tinted with 1.0 wt% PV23 colourant.Additional screening tests were conducted to determine the effects of type and degree of alkoxylation on colour strength and rub-out with a series of acetylenic diol ethoxylates (TMDD-4EO, TMDD-10EO and TMDD-23EO).

Figure 4. Comparison of colour strength and rub-out (E) values obtained for PV23-tinted waterborne acrylic paint containing 1.0 wt% TMDD alkoxylate surfactants.

Figure 4. Comparison of colour strength and rub-out (E) values obtained for PV23-tinted waterborne acrylic paint containing 1.0 wt% TMDD alkoxylate surfactants.All the alkoxylated acetylenic diols significantly improved the colour strength obtained on tinting the acrylic base paint with the colourant. This is not surprising as dynamic wetting agents can enable more efficient wetting of pigment particles to enable better dispersion of the pigment particles; as long as the polymeric dispersant present in the formulation can stabilize these smaller pigment particles, higher colour strength results.

Both colour strength and rub-out (DE) values improved to more significant extent as degree of ethoxylation decreased especially with TMDD-EOPO.

A similar study was conducted using the same waterborne acrylic base paint but tinting it with 1.0 wt% of a pigment blue 15:3 (Figure 5).

Figure 5. Comparison of colour strength and rub-out (E) values obtained for PB15:3-tinted waterborne styrene-acrylic paint containing 1.0 wt% alkoxylated surfactants.

Figure 5. Comparison of colour strength and rub-out (E) values obtained for PB15:3-tinted waterborne styrene-acrylic paint containing 1.0 wt% alkoxylated surfactants.The base paint has good colour acceptance already and only the highest HLB alcohol ethoxylate (AE HLB 18.2) can improve both the colour strength and the rub-out (DE) for this base paint-colourant system (Figure 5). This is likely due to the ability of AE HLB 18.2 to provide steric stabilization – acting as a co-dispersant – to improve the overall stabilization of the white pigments and fillers in the base paint.

Conclusions

The experiments conducted in this study have demonstrated that nonionic surfactants, like alkoxylated acetylenic diols, that lower dynamic surface tension are also often effective at increasing the colour strength achievable on tinting a given base paint. Additionally, alcohol ethoxylates – particularly those with higher HLB values – are often able to improve colour acceptance presumably because of their ability to provide steric stabilization to pigments and fillers. All these additives can stabilize the pigments during surfactant/dispersant re-equilibration after mixing.