High-level know-how, innovations in painting processes and an ever-greater push towards the sustainability of processes and material – this month's hot topics.

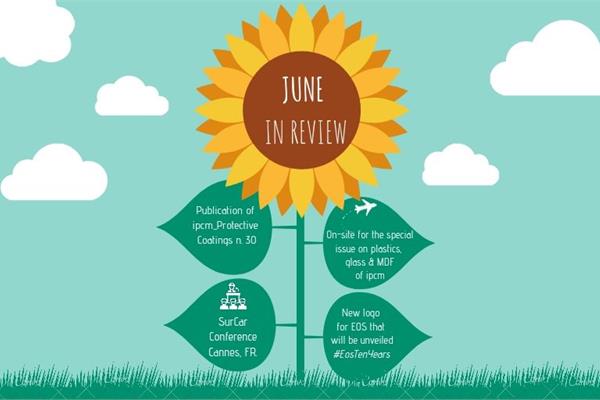

According to experts, this June is rightly one of the hottest months of the last ten years. The heat wave that greeted the official beginning of summer also brought with it the second issue of the year of ipcm_Protective Coatings, our magazine dedicated to corrosion control and prevention technologies.

June is also a month where much of our time is dedicated to on-site reporting in preparation for the July issue of ipcm® and also the August edition of ipcm® Ibérica/LatinoAmérica.

We have visited several companies and you will be able to read about these in the pages of the upcoming issues. For the ipcm® special on plastics, glass and MDF, we met several plastic materials coaters: a fast-growing sector but which requires in-depth skills and a high degree of research. What stands out is an ever-greater push towards innovation and quality all round, which now also reached those industries where before the finishing had a marginal importance.

This is due to the will to share knowledge across the finishing industry and between the different players in the market – a practice that is the basis of many business relationships in the sector and is vouched for by the companies visited and events such as SurCar, the congress dedicated to finishing in the automotive sector, held on June 27th and 28th in Cannes, France.

ipcm® had the opportunity to participate at the two-day event and to exclusively interview some of the major global players in the auto sector. What emerged is the need for OEMs to be increasingly flexible in terms of production in order to cope with the new players in the market, the contraction of the market itself, new technologies - such as autonomous driving - new colour trends and the generational change, which in turn has led to changes in terms of purchasing and consumption.

Even the coating process is obviously affected by these trends and innovations, and must be flexible and quickly able to adapt – today more than ever – to cycles, materials and technologies that are constantly changing. Research is constant and the road to innovation seems to lead to two-colour applications with no overspray and no need for masking, low-temperature curing and four-layers wet-on-wet cycles.

Another topic that is been extensively addressed is sustainability. From electric cars to emission regulations right up to sustainable processes and materials: sustainability is more alive than ever and the car industry is at the forefront in its innovation.

Speaking of sustainability, we also want to keep contributing to highlighting the efforts of companies in the sector to pursue the best practices in terms of sustainability: after a brief summer break, you can read the second instalment of the interview "5 on 5 on Sustainability" in the September issue of ipcm.

Last but not least, we defined the final details of our corporate video, choosing the frames and the voices that will tell our journey during these first 10 years of EOS.

The video will be previewed during the celebratory event on July 24th. During the night – which everyone will be able to follow through the hashtag #EosTenYears on Instagram, Facebook and LinkedIN – the new EOS logo will also be unveiled. It has been redesigned in a new and fresh graphic, witnessing the aurora which arises every day since that July 24th 2009.