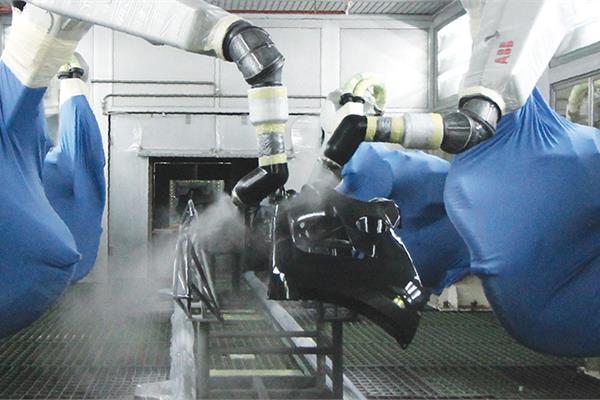

Maserati has recently installed two new generation robots built by CMA Robotics for the flame hardening of plastic components. This has guaranteed greater compliance of painted surfaces to quality standards, significant operational savings in terms of process and consumption, and greater operator safety thanks to an innovative access system that was tailor-made for this factory.

Estimates in the field of robotics are only partly reassuring: in its preliminary World Robotics Report, the International Federation of Robotics (IFR) wrote that 384,000 robotic devices were sold worldwide in 2018, i.e. one percentage point more than the previous year1. According to the findings of the international association, Italy ranked fifth in Europe and tenth on a global level in 2018, with 190 robotic systems installed for every 10,000 employees.

Eastern countries lead the ranking: South Korea is firmly in first place since 2010, with 710 robotic systems for every 10,000 employees.

The automotive industry is the main beneficiary of the Industry 4.0-oriented developments in this sector: from welding and assembly to coating and sealing, every stage of a car manufacturing process involves the use of increasingly cutting-edge and high-performance robots. In the Mirafiori plant (Turin, Italy), the bumpers of the

Maserati Levante car model are coated.

It has replaced its robotic devices with two new generation robots built by CMA Robotics (Pradamano, Udine, Italy) for

the flame hardening of plastic components. This has guaranteed several strategic advantages for its coating process,

including greater compliance of painted surfaces to quality standards, significant operational savings in terms of process and consumption, and greater operator safety thanks to an innovative access system that was tailor-made for this factory.

Keep Reading