The pilot project is being hailed as a milestone in defossilisation, proving that high-quality plastics for demanding automotive applications can be produced without fossil raw materials.

BASF, Porsche and Austrian technology partner BEST have successfully completed a pilot project demonstrating how mixed waste from end-of-life vehicles can be recycled into high-performance plastics for use in new car components.

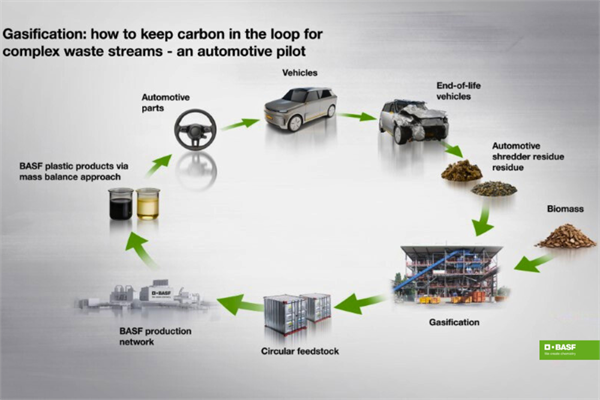

The project focused on automotive shredder residues (ASR) – a mixture of plastics, films, foams and paint residues that are typically too complex to be mechanically recycled and are instead incinerated. By using gasification, a form of chemical recycling, the partners proved that these materials can be transformed into new raw materials and returned to the automotive value chain.

For the first time, fossil raw materials were fully replaced by a blend of automotive waste and biomass, with the resulting synthesis gas and derivatives used in BASF’s production network. The recycled raw material was then applied to manufacture polyurethane formulations, enabling the production of steering wheels made entirely from non-fossil feedstock.

“Pilot projects like these allow us to evaluate how we can further develop the circular economy as a sustainability field at Porsche and how we can anchor chemical recycling in our strategy in the long term. We are testing new recycling technologies with our direct partners in order to increase recyclate quotas, gain access to previously unusable recyclate sources and evaluate new processes for waste streams that are currently being thermally utilised,” has stated Robert Kallenberg, Head of Sustainability at Porsche AG.

Porsche has set a target of raising the proportion of verifiable secondary materials in its vehicles, and sees chemical recycling as a complement to mechanical recycling, particularly where high quality and safety standards must be met. The approach could be scaled up using the mass balance method, in which recycled feedstocks are allocated to final products through certified accounting.

“In our plant, we have previously converted biomass such as wood or straw into chemical raw materials. In this pilot project together with BASF and Porsche, we have now used this gasification technology for the first time to convert complex plastic waste streams together with biomass into synthetic crude oil, known as syncrude. This form of chemical recycling has great potential for converting complex, mixed waste streams into new, valuable raw materials. It thus represents a sensible alternative to waste incineration,” has added Matthias Kuba, Area Manager Syngas Platform Technologies at BEST in Vienna.

“At BASF, we coordinate our sustainability efforts on our plastics journey which consists of three key steps in the product lifecycle: make, use and recycle. We prioritise mechanical recycling and continuously improve its efficiency. At the same time, the type of waste and the degree of sorting determine which technology is best suited. We are convinced that complementary technologies such as chemical recycling, which includes pyrolysis, depolymerisation and gasification, are necessary to further promote the circular economy and reduce the plastic waste that still ends up in landfills or is incinerated today. To optimally utilise the various waste recovery options and further develop all technologies in parallel, the appropriate regulatory framework is essential,” has concluded Martin Jung, President of BASF’s Performance Materials division.