BvL Oberflächentechnik GmbH delivered a customised cleaning solution for bearing housings and roller bearings to ensure greater reliability and efficiency in rail vehicle servicing for one of Austria’s leading railway and mobility service providers.

Thorough cleaning of heavily soiled components is a crucial part of rail vehicle maintenance. Only properly cleaned parts allow for accurate servicing, dependable quality assurance, and effective crack detection.

To address these stringent requirements, BvL Oberflächentechnik GmbH has engineered a bespoke cleaning solution that accommodates both bearing housings and cylindrical or tapered roller bearings within a single intelligent system, developed for one of Austria’s leading railway and mobility service providers.

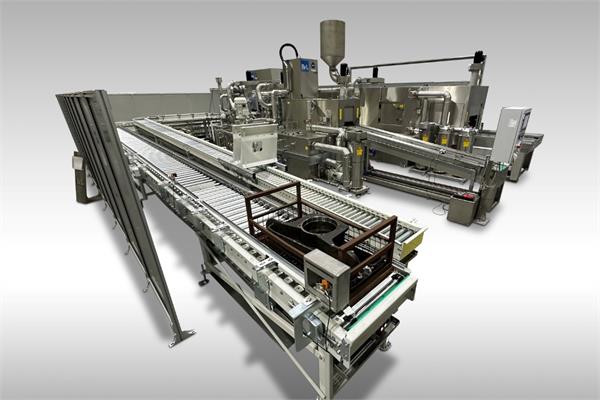

For this specific application, two Yukon continuous flow systems are employed. One is dedicated to cleaning the bearing housings, while the other handles the cylindrical and tapered roller bearings. The systems are interconnected to ensure seamless operation.

A distinctive feature is the integrated counting register, which prevents components from different sets from being mixed up. Each set — consisting of bearing housings, covers, and the corresponding cylindrical roller bearings — remains uniquely identified throughout the entire cleaning process. This significantly enhances process reliability.

Both continuous flow systems operate in synchronised mode and are connected via roller conveyors. This setup enables automatic component transport from the loading to the unloading station, ensuring simple and safe handling. Before cleaning, the bearings are manually removed from the housings and placed in separate baskets, which are then fed into the respective cleaning systems.

While the cylindrical and tapered roller bearings pass through the first system, the housings are cleaned and dried in the second system simultaneously. The separate arrangement of the loading and unloading stations ensures that clean and dirty components never come into contact.

The first cleaning system guides the bearings through multiple zones for cleaning, rinsing, and blowing off. A technical highlight is the lowerable nozzle system, which envelops the bearings to deliver particularly intensive and targeted cleaning of internal areas.

In the second system, the housings are completely dried using vacuum drying following the cleaning and rinsing stages.

The entire system is enclosed, guaranteeing clean and safe operation. The control cabinet was installed above the system at the customer’s site to save space, with a compact central control panel providing simple and convenient operation.

The design was precisely tailored to the customer’s spatial requirements, and all mechanical and electrical interfaces were optimally coordinated to allow smooth integration into the existing production lines. Close cooperation with Austrian partner company Glogar GmbH enabled direct on-site support and close coordination throughout the project phase.

A well-structured bath maintenance concept extends the service life of the cleaning media and enhances cost-effectiveness. Additionally, various smart cleaning functions contribute to energy efficiency and process reliability. A remote maintenance facility allows direct service support, while thermal insulation minimises energy losses.

BvL cleaning systems are individually designed to meet each customer’s specific requirements. Modular equipment options — such as integration with Geyser high-pressure technology — enable even demanding tasks, including the removal of clinging chips. All cleaning processes are tested in advance at the company’s own technology centre, ensuring they are perfectly adapted to the intended application.

In addition, BvL Oberflächentechnik GmbH offers a wide portfolio of cleaning solutions for the rail industry — ranging from large-scale systems for wheel sets and bogies to specialised systems for motors, stators, and numerous other components.