Discover IST’s recently launched innovations, the TW; a series of sustainable, efficient and modular washing machines for process and storage tanks, and the Roto Plus; a market-first in gravimetric filling as well as a new integrated-heating system and the Disti-link microcontroller touch-board system. Read Alessia Venturi’s exclusive interview scoop with Massimiliano Mingacci, Global Sales and Marketing Manager of IST and his company’s revolutionary machines exclusively in the May issue of ipcm® magazine.

The team from Italia Sistemi Tecnologici SpA (fondly known in the industry as IST), have unveiled two new secret weapons—the TW and the Roto Plus.

On 28 March, at a much-anticipated live launch at the European Coatings Show in Nuremberg, an interested audience listened intently as presenter Massimiliano Mingacci, the Global Sales and Marketing Manager for IST, focused their attention towards the sustainability, efficiency and modularity behind their new machines; concepts which although current nowadays, have since its foundation, been intrinsic to IST’s corporate dna.

"2023 is already a year to remember for IST," explained Mingacci, “the launch of our latest machinery, control systems and software; the restructure of our management team including the entry of new figures, the consolidation of historical positions within the company and the expansion of our sales network and technical support team for fast and global assistance, are all just some of the major improvements that we are implementing in our Italian headquarters in Modena.”

The impressive results obtained in recent years by IST show a growth and industrialisation, started over 10 years ago, that has been well received and supported by the entire team.

"Thanks to the commitment and proactivity of our team, we have overcome the typical obstacles encountered on the road to growth and continuous improvement. Our numerous export activities, over the past 35 years, have given us a global view of the market and provided us with the capabilities to analyse the data and signs that we receive from the industry in order to adapt our modus operandi to changing market conditions. In today's washing and recovery industry there are many reasons to develop new concepts and introduce more efficient and sustainable solutions and IST is here to significantly contribute to this field," continued Mingacci.

In the well-known and complete line of products for recovery and washing, IST has implemented various automatisms and customisations to make its systems integrable with existing systems, making IST a point of reference in the sector.

Among the novelties presented by IST at the European Coating Show, visitors could not help but notice two devices of visual impact that exposed an important revolution in the coating field and that will be marketed from the second half of 2023.

TW – Control of the cleaning process

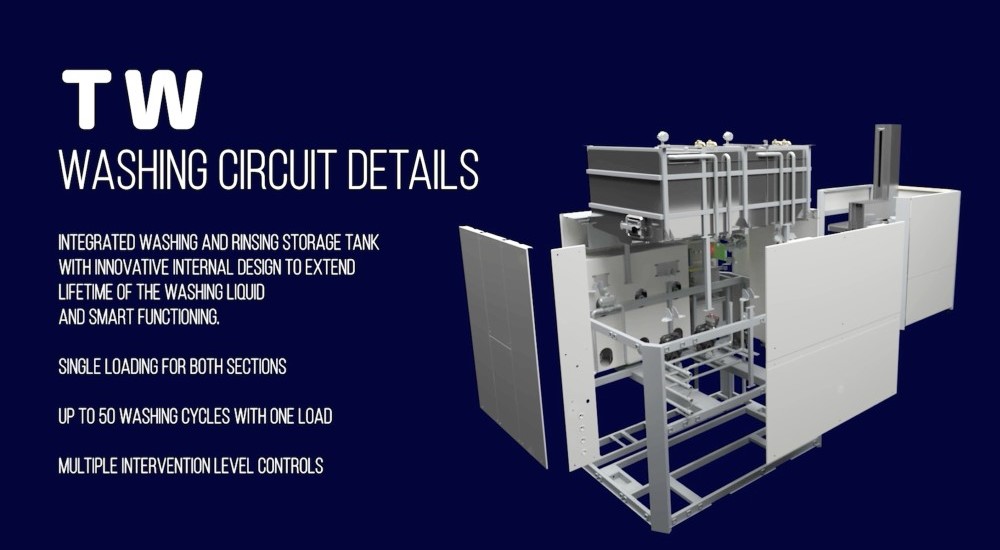

The TW is a revolutionary new series of washing machine for process and storage tanks designed above all for users and maintenance technicians.

IST’s concept is based on a unique modular design which allows the TW to be configured according to specific requirements and to structure and enhance tidiness in the workshop washing area. The compact size also makes it possible to install the unit anywhere it is required, and even with an optional double washing bay, the footprint is limited.

Made of sturdy painted steel, the TW consists of a single structure to enclose pumps, control panel, storage tanks and washing bay; entrance of which may be orientated, where most convenient to the operator. The bay can be completely customised and adapted to specific needs; to increase washing output and reduce downtime it is possible to have a second washing bay—not necessarily made as the first—to wash different kinds of vessel/tank/IBC. The bay can also be buried to load at floor height.

SAFETY

Paramount in all IST products, safety is no exception in the TW. The manual washing of process or transport containers is complex, inconvenient and a dangerous operation for those who must perform it, due to the exposure to dangerous chemical substances and the non-ergonomic movements needed to reach the internal surface. The products currently on offer in the market are complicated, unergonomic and not designed with users in mind.

TW incorporates cutting-edge technology, combined with ATEX explosion-proof certification that makes it unmatched in the industry. It is a sustainable and efficient solution that structures the washing and process of waste management areas by offering operators complete safety to perform in only ergonomic activities; increasing cleaning results as well as the quality of work. The compact modular design, the extreme simplicity of use and the operational safety mark the border with the past in the washing sector of any type of container.

"The needs and requirements of users are changing rapidly, and so must a solution provider and not just its products. It is also, for this reason that we are increasingly recognised as a brand and not as a commodity, which instead happens to other companies operating in our sector", comments Davide Govoni, Product Manager of IST and leader of the TW project.

ROTO PLUS – Evolution in solvent recovery

"Welcome to the future of solvent recovery," with these words Alessandro Galli, Product Marketing Manager of IST, presented the next evolution of IST technology, "there are over 500 units of the well-known ROTO PLUS series currently on the market. Thanks to the safety, simplicity and reliability, of these machines, we have managed to generate results beyond our expectations; such is the success of the Roto Plus, originally designed as a niche line for our business, that the series has manifested itself into becoming the driving force behind our growth. With the evolution of the ROTO PLUS we wanted to eliminate the whim of proposing a technically unparalleled machine, and to offer instead never-before-seen technology to our customers that we believe will allow us to expand into new sectors."

The conditions seem to be all there: a kettle with new geometry and innovative insulation to increase the efficiency of the unit, a new integrated heating system to increase periodic maintenance intervals, the advanced DISTI-Touch control system on board the machine, the gravimetric control of the boiler load and finally the DISTI-Link monitoring and data recording software.

For more information on the TW please visit: www.tank-washer.com

or for the Roto Plus please visit: www.roto-plus.com

or to discover more about IST products visit: www.ist.it