Ever wondered just how much energy your coating line is consuming? Or what the most efficient way to lower your energy consumption would be? The HangOn Green Effect provides a solution with enormous hidden potential.

The coating industry is very energy demanding. This is a fact that has been known to us for long, but we never knew exactly how much energy that escapes during the process. Now we know.

Petter Törefors is the CEO and owner of HangOn AB, Swedish developer and manufacturer of solutions for hanging, masking, and handling. A recent study conducted by HangOn, assisted by surface treatment expert Anders Jansson, Meyer & Hjort AB, shows surprising results.

– Regardless of how much goods you fill the line with, the energy consumption is constant up to between 80 and 90 percent. For example, increasing the goods flow times five per hour with HQC-hanging instead of regular hooks, will only increase the total energy consumption with 18 percent, Törefors says.

This game changing conclusion for the coating industry makes the opening for “The HangOn Green Effect”. The secret is spelled increased hanging density. A simple step to undertake that will make a huge difference by cutting costs, increasing profit while at the same time making the coating industry greener.

– This is the most effective means to reduce energy consumption in a coating line. By hanging the goods in a more efficient way you can cut your consumption up to 75 percent – if you count the cost of energy consumption per coated detail, Törefors says.

A coating line will always suffer from energy loss in the outer surfaces, ventilation and by heat leakage through openings. In times when energy prices are skyrocketing you need to be smart and use the energy wisely.

– This is very important to understand. You shou should not calculate your energy cost per hour in your coating line. You should calculate with energy cost per item produced. And the key to lowering the energy cost per item produced is to evaluate how you are hanging the items on your line, Törefors says.

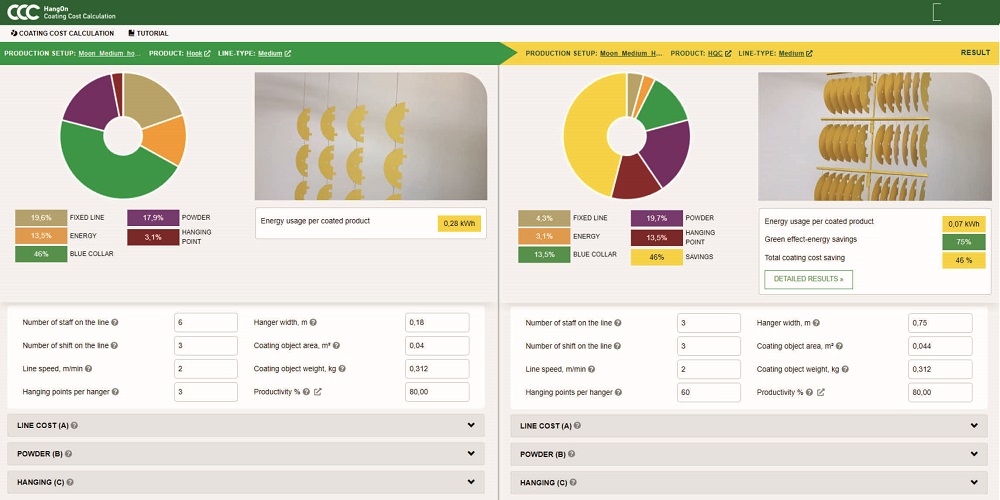

However, you can also cut costs up to 46 percent on the coating process as a whole, going from 0,28 kWh per coated product down to 0,07 kWh per coated product if you choose to increase the hanging density. These numbers need do make their way to the decision makers in every coating facility, Törefors says.

– Hanging the goods is mainly a task that is handled on the workshop floor, but this is a question for management to address. The HangOn Green Effect makes a difference in reducing energy consumption and this is by far the biggest impact we can make for sustainability.

With the coating cost calculation tool on the HangOn website (https://ccc.hangon.com/) you can compare the numbers in standard scenarios in five standard coating lines. You can also fill in the blanks with your own numbers if you like, to check the facts. This is a great way for validation of the numbers in your own coating facility.