Façade coatings have to combine attractive appearance with reliable protection from weathering effects. Silicone resin paints ensure this functionality and in addition, modern silicone resin emulsions provide broad color selection and slow façade pollution. Of course, they meet all regulatory requirements.

High water vapour diffusion, low water absorption

In order to ensure that moisture does not accumulate in the brickwork and cause e.g. blistering problems, façade paints must promote easy diffusion of water vapor. High water vapor diffusion is achieved by formulating with supercritical pigment volume concentration at which the binder does not fill all the interstitial spaces of the filler and pigment particles - thus allowing a network of micropores to be formed. Since hydrophilic pores absorb water strongly, these pores create a surface prone to attack by penetrating water, such as rain. The pore surfaces must, therefore, be made hydrophobic – without heavily impacting the microporous structure that makes water vapor diffusion possible. In practice, this is achieved by the addition of silicone resin emulsions like TEGO® Phobe 1659. If formulators want to add a water beading effect caused by high surface contact angle with water, emulsions of modified siloxanes like TEGO® Phobe 1409 can be added to the formulation.

Low dirt pick-up

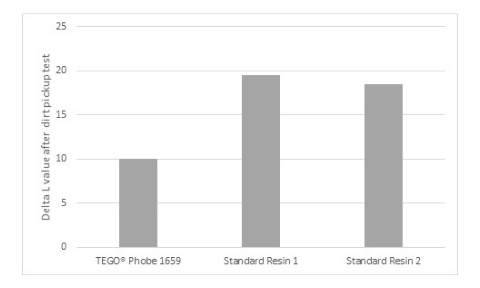

In an accelerated soiling test in the laboratory that simulates outdoor weathering, façade paints based on TEGO® Phobe 1659 pick up dirt only half as much as the market standard (Figure 1). For this test, water is treated with a dirt mixture consisting of tar, carbon black, and Japanese Norm Dirt. Test plates coated with silicone resin paints are soiled with this water, heated to 50 °C and washed with clean water. This cycle is repeated several times.

Delta L value after dirt pickup test

Delta L value after dirt pickup testBeyond white – façade paints with various colors

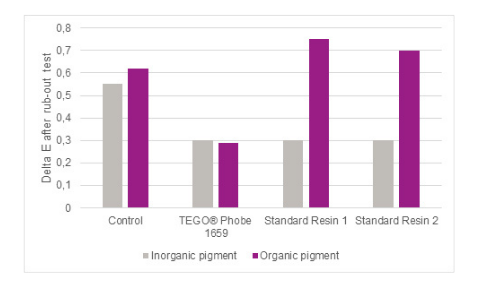

The high pigment affinity of modern silicone resin emulsions like TEGO® Phobe 1659 is also important for pigment concentrate incorporation. Tinting tests show that formulations with this silicone resin emulsion allow superior tinting behavior not only with pigment concentrates based on inorganic pigments but also based on organic pigments – which is a challenge for other market standards (Figure 2). In addition to low Delta E values after rub-out test, the use of TEGO® Phobe 1659 also provides high color strength allowing low dosages of the pigment concentrates.

Delta E after rub-out test

Delta E after rub-out testUse in plasters - advantages in processing and storage

In addition to the use in façade paints, silicone resin emulsions like TEGO® Phobe 1659 are also suitable for liquid plasters. In this application, TEGO® Phobe 1659 offers advantages in processability because of a very favorable rheological profile e.g. without creation of too strong yield points. This simplifies application for the processor significantly.

Favorable regulatory profiles

With regulatory demands increasing constantly, it gets more and more important that raw materials offer favorable regulatory profiles and can be used to formulate in compliance with the EU Ecolabel or other standards like Blue Angel or Nordic Ecolabels. This is the case for modern silicone resin emulsions like TEGO® Phobe 1659.