The new energy-efficient production of reusable stainless steel blasting media from VULKAN INOX reduces carbon footprint.

The manufacturer of highly efficient, durable and reusable stainless-steel abrasives VULKAN INOX GmbH has recently announced that it will showcase the sustainable CHRONITAL and GRITTAL blasting media at GIFA, the international trade fair dedicated to foundry that will take place from 12th

to 16th June 2023 in Düsseldorf (Germany).

The high dimensional stability of the individual stainless-steel grains prevents the formation of dust and noticeably improves working and visibility conditions. In addition, their use reduces the amount of waste and the cost of disposal.

In the induction furnaces, the stainless-steel is melted and then atomised to create the spherical blasting abrasive CHRONITAL, that is mainly suitable for cleaning, deburring and edge rounding. The angular blasting media GRITTAL, on the other hand, is formed by crushing the granules.

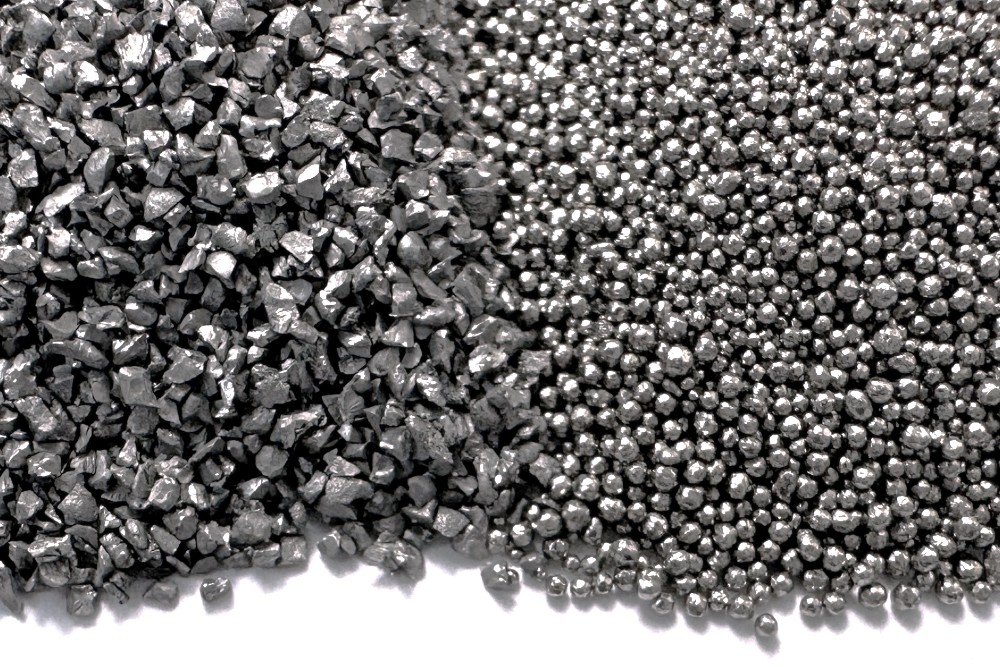

The angular blasting media GRITTAL (left) and the spherical blasting abrasive CHRONITAL (right)

The angular blasting media GRITTAL (left) and the spherical blasting abrasive CHRONITAL (right)

The reusable stainless steel blasting abrasives, which are produced exclusively with renewable energy since 2022, are manufactured starting from melted steel scrap and are completely recycled back into the metal cycle. So, the CHRONITAL and GRITTAL blasting abrasives improve the eco-balance of the customers, because the media has a significantly smaller CO2 footprint.

“The customers are making great efforts to reduce their own footprint. So, we have made many adjustments: as a starting material, we deliberately buy secondary input materials with a low CO2 footprint. Since 2022, we have been operating our induction furnaces with electricity generated from renewable sources and implementing waste heat recovery to power the drying process. Overall, we have reduced CO2 emissions from our own and third-party energy sources (Scope 1 and 2) by 87% since 2018. This means we are conserving valuable resources. Our goal is to convert the entire process so that gas will no longer be required,” has stated Christian Hoffmann, the sales manager of VULKAN INOX.

VULKAN INOX will be at booth n. G09 in hall 16.