Zinc dust paints based on Dynasylan SIVO 140 and ultra-high solid topcoats based on SILIKOPON EF enable the formulator developing low VOC coating systems. The VOC emission can be reduced from 120 g/m² to 20 g/m² compared to a common solvent born coating system. This reduction is environmentally friendly and protects steel from corrosion.

Perfect team for eco-friendly corrosion protection systems

More than any other sector, the corrosion protection market illustrates the impact the use of perfectly tailored binder and pigment systems can have on the function of the coating as a whole and furthermore on the protection/durability of valuable objects.

The combination of two especially eco-friendly binder systems is presented.

Primer based on a waterborne silane

The waterborne silane system was developed for use in two-pack zinc dust paints, which are the coating of choice for long-term corrosion protection.

The binder contains special organofunctional groups which can interact with the filler and stabilize the formulation. Formulations based on the waterborne silane binder can be used to formulate nearly VOC-free zinc dust paints.

Guiding Formulation based on waterborne silane-based binder:

|

COMPONENT

|

PARTS BY WEIGHT

|

|

Dynasylan

® SIVO 140

|

15.0

|

|

Deionized water

|

4.0

|

|

TEGO

® Wet 270

|

1.0

|

|

TEGO

® Twin 4100

|

0.5

|

|

AEROSIL

® 200

|

0.6

|

|

Zinc oxide (Red Seal, Ever Zinc)

|

8,0

|

Mica MKT

|

7,9

|

|

Zinc dust powder (4P16, Ever Zinc)

|

63,0

|

|

Total

|

100.0

|

Silicone hybrid resin for corrosion protection applications

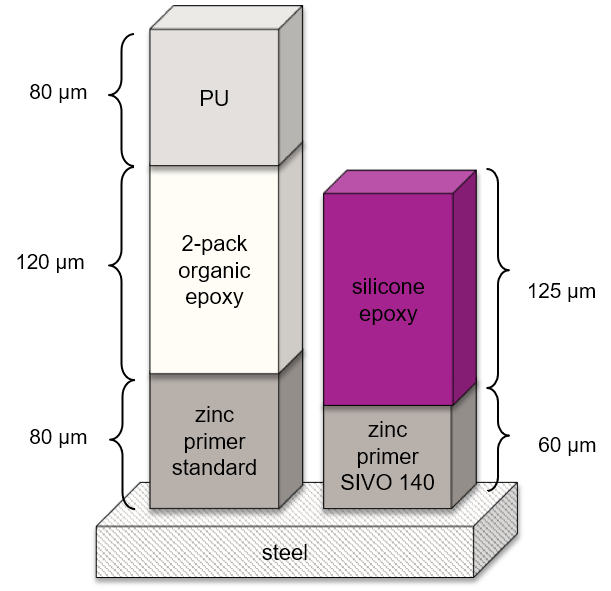

Conventional coating systems for heavy corrosion protection are based on a three-layer system, specified in ISO 12944 (C5, high). The abilities of the intermediate epoxy layer and the PU top coat can be combined by a one layer formulation of the silicone hybrid resin cured with an amino alkoxy silane (Figure 1)[1].

This technology provides coating systems with significantly less than 250 g/L VOC (sometimes even less than 100 g/L) and moreover permits isocyanate-free crosslinking.

Reduction of three to two coating layers:

Using a combination of low-VOC zinc dust primer based on waterborne silane binder and top coats based on a silicone hybrid resin.

Fig. 1: Advantages of silicone hybrid resins.

Fig. 1: Advantages of silicone hybrid resins.

This two-layer system spares costs and time:

- material cost

- labor cost

- production time

By reducing the film thickness, less coating materials are needed and labor costs are reduced significantly

[2]. Moreover, the working time is considerably reduced due to less coating layers and less curing time[2].

Eco-friendliness (VOC-regulations)

Zinc dust paints that are formulated with this innovative binder and ultra-high solid top coat based on the silicone hybrid resin, enable the formulator to develop low-VOC coatings systems without compromising properties[2].

The VOC emission can be reduced from 120 g/m² to 20 g/m² compared to a common solvent borne coating system.

This reduction not only protects the substrate, it also protects the environment. The eco-friendliness is obvious, because of the reduced coating thickness and hence less material using less solvents.

Guiding Formulation based on the silicone hybrid resin:

|

COMPONENT

|

PARTS BY WEIGHT

|

|

SILIKOPON

® EF

|

55.0

|

|

TEGO

® Foamex 840

|

0.7

|

|

TEGO

® Wet 260

|

0.6

|

|

AEROSIL

® R 972

|

1.0

|

|

BENTONE

® SD-2

|

0.5

|

|

FINNTALC

® M40

|

8,0

|

Blanc Fixe ZB

|

20.0

|

|

Black FW 200

|

1.5

|

|

butyl acetate

|

10.7

|

|

butyl glycol acetate

|

2.0

|

|

Total

|

100.0

|

|

coating properties

|

|

|

theoretical solids content

|

~ 87%

|

|

density coating

|

1.27 g/cm³

|

|

cup efflux time (DIN 6)

|

15-18 s

|

|

VOC (calculated)

|

~ 170 g/l

|

|

mixing ratio

|

|

|

hardener: Dynasylan

® AMEO

|

|

|

coating: hardener =

|

100 : 12.8

|

Test results

The corrosion protection performance was investigated with coatings on blasted steel, according to DIN EN ISO 12944-6 (C5 high, test program 1). A standard three-layer coating, a commercial 2-pack zinc dust epoxy-primer, a 2-pack epoxy-intermediate layer, and a 2-pack polyurethane top coat (in total: 280µm dry film thickness) were compared to the two-layer combination of the waterborne silane-primer with the 2-pack silicone hybrid top coat (in total: 185µm dry film thickness).

Photos: After 1440 hours of neutral salt spray test, according to ISO 9227

Photos: After 1440 hours of neutral salt spray test, according to ISO 9227

In the humidity chamber test, carried out according to ISO 6270-1, no difference could be detected. Both coating systems showed no blistering after 720 hours exposure. However the adhesion on the two-layer system was better (GT 0-1 versus GT 2).

Another advantage, which is achieved with top coats based on silicone hybrids, is the higher chemical resistance. The coating was exposed at room temperature to 10% solutions of sodium hydroxide and of sulfuric acid; no damage was evident on the paint surface. Surfaces based on silicone hybrids also show a good performance in terms of easy-to-clean-properties and good abrasion resistance.

Summary

The high crosslinking of coatings based on a silicone hybrid resin qualifies this binder-technology for highly durable coatings - extraordinary gloss, color retention and weather resistance. Compared with a conventional three-layer system, this two-layer system has better corrosion protection, even though the dry film thickness is 95 µm less.

In combination with the waterborne zinc dust primer, based on silane, we achieved an eco-friendly coatings system, which offers a brilliant solution for the reduction of solvents and material and thus the reduction of costs and additionally provides a long-lasting protection against the formation of micro-channels.

References

[1] B. Bröskamp, F. Böss, S. Herrwerth, Ch.

Cova-Hög, Ressource Efficient Corrosion Protection, ECJ 03/2015

[2] M. Hallack, Flyer, Perfect Team for Eco-friendly Corrosion Protection Systems, ECS, 03/2019