SPM SpA, a benefit corporation, has embarked on a pioneering journey in the world of automotive coating by installing a state-of-the-art plant designed to perform complete, high-performance, water-based cycles. The result of an intense R&D activity in collaboration with CAT Automation, the new automated system combines sustainability, application precision, and aesthetic-functional quality, anticipating the environmental and production needs of the future.

For years, the automotive industry has been trying to find a balance between high-performance finishes, aesthetic quality, and sustainability. This has proven to be a particularly complex goal. Unlike other industrial sectors, the use of water-based paints, known for their lower environmental impact compared with solvent-based formulations, is still not widespread, although it has been growing significantly over the past decade. This is demonstrated by numerous articles published by ipcm®_International Paint&Coating Magazine in the last few years, reporting about coating systems where at least one of the layers making up the bodywork finishes was water-soluble.

Currently, these paint products are used almost exclusively as base coats, and more rarely, as primers; top coats, whether transparent or pigmented, continue to be formulated with solvents, offering greater reactivity, faster drying times, and excellent performance in terms of adhesion, gloss, and resistance. However, they also have a significant environmental impact due to the emission of volatile organic compounds (VOCs), although these have been significantly reduced by high-solid formulations.

Water-based paints, on the other hand, require longer cross-linking times, are more sensitive to humidity, and require greater application accuracy. At the same time, research and development over the last twenty-five years have ensured a degree of aesthetic and mechanical performance comparable to that of solvent-based coatings, passing the rigorous tests required by the technical specifications of car manufacturers.

While it is true that such specifications impose particularly stringent requirements for bodywork coating, they are slightly more flexible for plastic components intended for the automotive sector. This allows developers of innovative formulations to enter a market that is increasingly receptive to new ideas and sustainable approaches. Some companies are also moving in this direction by investing heavily in application technologies that can enhance the potential of water-based formulations. Among these, SPM stands out for the implementation of a complete water-based coating cycle, including primer, finish, and top coat application, thanks to the system designed by CAT Automation. Combining sustainability, aesthetic quality, and performance, this innovative solution sets the stage for a new generation of finishes in the automotive world.

SPM’s cutting-edge project

SPM SpA (Brissago-Valtravaglia, Varese, Italy), a benefit corporation specialising in the production of plastic and aluminium components for the automotive, fashion, and sports equipment industries, has recently invested in a major strategic conversion of its coating line. “When we decided to install the new system[1], we aimed to build a future-proof solution capable of meeting the needs of the market over the next ten to fifteen years. And the key trend for the future is undoubtedly sustainability,” says Stefano Berutti, Head of the Automotive Division at SPM.

Adopting a completely water-based cycle required extensive research and development by SPM, encompassing both chemistry, to identify the ideal coating system that could pass the stringent OEM tests, and plant engineering. “Traditional lines designed for solvent-based paints are not compatible with the specific characteristics of water-based products, as these require different drying times, ventilation systems, and differently designed ovens. In addition, until our project, no complete water-based coating cycle had ever been tested on a large scale in a real production context within the automotive sector. The first objective was precisely this: to guarantee a performance degree that could stand up to comparison with traditional cycles. The second goal was even more challenging: to design a system capable of applying these paints correctly,” adds Berutti.

The project, carried out with the technical support of CAT Automation (Val della Torre, Turin, Italy), was made possible thanks to access to a funding opportunity for the design and development of low-environmental impact, water-based coating plants for the automotive industry, promoted by the Lombardy Region and aimed at supporting innovative projects in the green and advanced manufacturing fields. The result was an automated system designed by CAT Automation and Cefla Finishing (Imola, Bologna, Italy), which not only applies water-based coatings but also high-solid, low-solvent products and 100% dry residue UV coatings.

Robotised cleaning and plasma pre-treatment

SPM processes components made of plastic, aluminium, or a combination of the two. For plastic parts, the production phases include moulding and a series of aesthetic and functional treatments, such as pad printing, PVD, hot lamination, and liquid coating, which was previously outsourced and now is carried out in the new plant. Aluminium components, on the other hand, are decorated with direct treatments on flat sheets. “The new plant has been designed primarily for coating plastic components, but it can also be set up to apply a final layer on aluminium products as well, in the future,” explains Berutti.

The coating cycle begins with the manual loading of parts onto racks moved by a floor conveyor. “A control panel is installed at the loading station, allowing the operator to select the ideal application cycle based on the components’ specifications and the type of coating to be used,” explains Sandro Conti, the owner of CAT Automation. The parts then enter the cleaning station, where a robot performs mechanical brushing using special bristles sprayed with isopropanol along with ionising nozzles to remove dust and other surface impurities.

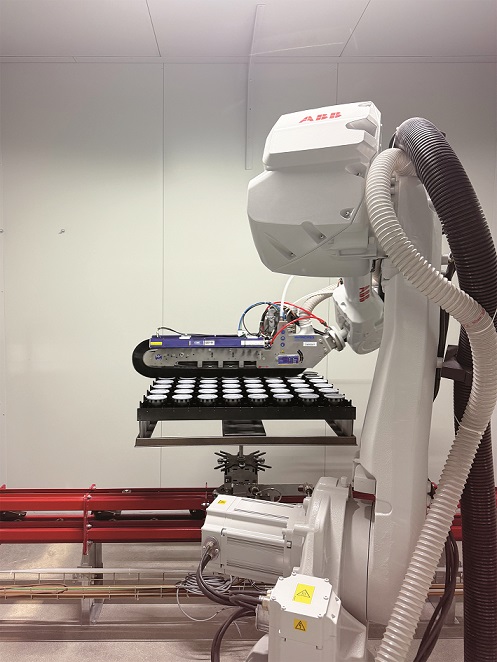

This is followed by the pre-treatment phase, where a greener technology, plasma, has been preferred over the flame hardening process, which is often used to activate plastic surfaces. “Applied by robots, this is a safer solution than flame hardening, which is effective but has poor parameter adjustability and therefore greater variability in results. We opted for plasma mainly to treat low-surface energy substrates such as polyolefins, in order to promote optimal paint adhesion,” says Conti. After pre-treatment, the parts move on to three booths, each equipped with an articulated robot installed by CAT, for the application of the primer, base coat, and clear coat, respectively.

The cleaning station, where a robot performs mechanical brushing using special bristles sprayed with isopropanol. © ipcm

The cleaning station, where a robot performs mechanical brushing using special bristles sprayed with isopropanol. © ipcm The plasma pre-treatment booth. © ipcm

The plasma pre-treatment booth. © ipcmRobotised application for greater precision and better overall process control

“Each booth is designed to apply both water-based and solvent-based paint thanks to a double gun and a double circuit system integrated into each of the three robots, which allow for quick and automated switching between the two cycles depending on requirements,” explains Mirko Perucchini, the coating plant’s manager.

“The robots we have supplied to SPM ensure high paint transfer efficiency: the amount of excess coating sprayed is minimal, indicating an extremely optimised application process that significantly reduces waste and maximises product consumption. This is the result of precise cycle engineering and careful adjustment of parameters based on each part’s geometry and each paint product type,” adds Conti. In addition, each application booth is equipped with a pre-chamber featuring a robot control panel, which allows monitoring specific parameters for that booth, as well as a dedicated paint management unit. “All application systems are fed by dosing units for one-component products and dosing and proportioning units for two-component ones.” Between one booth and another, there are intermediate flash-off areas calibrated according to the type of product applied.

Finally, the components reach the polymerisation oven, which generally operates at a temperature of approximately 80 °C but can be set to significantly lower values when using other types of paint. “On average, the parts dwell in the oven for 45 to 90 minutes before reaching the cooling area and, finally, the unloading one. When we use UV paints, which we only do with specific types of components, we perform a solvent evaporation stage at low temperatures and then expose the workpiece to ultraviolet lamps for a very short time for final drying,” indicates Perucchini.

The components dwell in the polymerisation oven for 45 to 90 minutes. © SPM

The components dwell in the polymerisation oven for 45 to 90 minutes. © SPM

The primer application booth, with robots supplied and installed by CAT Automation. © ipcm

The primer application booth, with robots supplied and installed by CAT Automation. © ipcmThe advantages brought by the new plant and by SPM’s relationship with CAT Automation

“The decision to rely on CAT Automation for the development of our new plant was not accidental: this company is recognised as one of the most knowledgeable in the field of robotics applied to coating, particularly with regard to the integration of advanced solutions for automated paint application,” says Stefano Berutti. “In addition to its high level of technological expertise, CAT has proven to be a reliable and responsive technical partner and supported us at every stage of the project, from layout design to start-up and optimisation. When working on an innovative project like this, which requires continuous experimentation and interaction, it is essential to have a flexible partner by your side that is available and willing to share its expertise. This is the only way to turn innovation into a real strategic advantage.”

The plant has been operational since the beginning of 2025 and has already brought numerous advantages. Although the economic benefits are still being assessed, given the short time since commissioning, SPM has found significant improvements in quality control and production time management. “Insourcing our coating phase has opened up new market opportunities for us, as many customers require such delicate and critical operations to be carried out directly by the manufacturer, who has greater control over the entire production process and can therefore offer guarantees of higher product quality,” explains Berutti.

Within the paint management unit, the application systems designed by CAT Automation. © CAT Automation

Within the paint management unit, the application systems designed by CAT Automation. © CAT AutomationSustainability and technological innovation

From an environmental perspective, the insourcing of the coating process has significantly reduced handling, thereby cutting CO2 emissions, costs, and time associated with road transport. This has also enabled SPM to accelerate its time-to-market and enhance its ability to fulfil orders more quickly. “Sustainability has always been a fundamental pillar for us: we were among the first companies to install solar panels in 2009, we doubled the capacity of our photovoltaic system two years ago, and since 2023, we have been using energy exclusively from renewable sources. Over the years, we have also invested in low-impact technologies, such as PVD, which replaces traditional galvanic processes containing hexavalent chromium and which we adopted some years ago, when the automotive market had not yet recognised the need for it. We have also installed electric presses with lower energy consumption, devices that use groundwater for our machining processes, adiabatic solutions to reduce energy waste, and consumption monitoring systems, demonstrating our concrete commitment to meeting environmental and ESG regulatory requirements.

“Thanks to our research and development activities and the implementation of the new coating plant, we are now in a position to offer low-environmental impact finishes that meet the high aesthetic and performance standards required by a demanding sector such as the automotive industry,” concludes Stefano Berutti.

[1] The installation of this innovative coating plant was made possible thanks to funding received from two subsidy schemes made available by the Lombardy Region, each contributing to covering specific items of expenditure in accordance with the relevant regulatory provisions:

- Ricerca & Innova, ERDF Programme 2021-2027, Axis 1 – Action 1.1.1

- Linea Sviluppo Aziendale, ERDF Programme 2021-2027, Axis 1 – Action 1.3.3