The new paint shop is being built at the CEER Manufacturing Complex in King Abdullah Economic City and is scheduled to begin production in the fourth quarter of 2026. It will be one of the most advanced automotive paint facilities worldwide, combining high levels of automation, flexibility and sustainability.

Engineering group Dürr

is installing an innovative and sustainable paint shop for CEER, the first Saudi automotive manufacturer and Saudi-born electric vehicle brand. The project, ordered in 2023, is now in the installation phase and represents the first full implementation of Dürr’s Paint Shop of the Future concept.

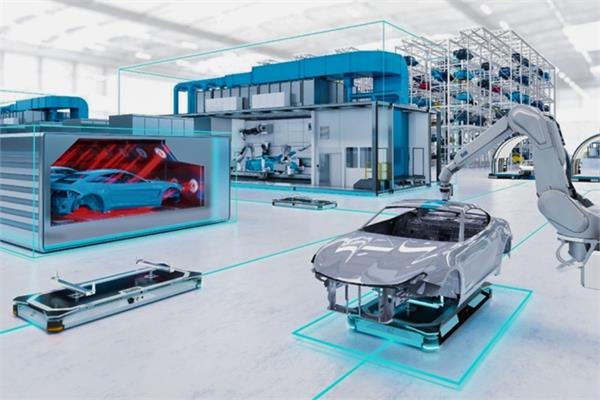

At the heart of the system is a modular layout in which automated guided vehicles (AGVs) transport car bodies flexibly between stations according to demand. Instead of conventional rigid painting lines, CEER is adopting Dürr’s box-based EcoProBooth concept, allowing interiors and exteriors to be painted within a single booth. The system also includes a dedicated box for fully automatic two-tone painting without overspray.

Dürr is supplying its latest generation of application and curing technology. This includes the EcoInCure oven, which heats vehicle bodies from the inside and significantly reduces energy consumption. The technology is particularly suited to electric vehicles, which feature heavily reinforced components for battery protection alongside thinner body sections. Compared with conventional systems, the process can reduce heating times by up to 30%.

Exhaust air from the ovens is treated using Dürr CTS’s electrically operated Oxi.X RV system, based on regenerative thermal oxidation (RTO). As the system operates without an open flame, it avoids the unwanted by-products of flame combustion while contributing to lower CO₂ emissions.

Another key feature is Dürr’s award-winning EcoPaintJet Pro, an overspray-free painting system that enables fully automated two-tone finishes. The technology eliminates the need for masking tape, reducing paint consumption and plastic waste, and can also apply complex designs such as lettering and logos.

“Innovation is a key driver of performance and sustainability in vehicle production. The paint shop of the future will deliver great flexibility, energy and paint efficiency, and exciting premium vehicle paint finishes. We are pleased to have the opportunity to partner with CEER to create one of the most modern car production lines in the world,” has stated Lars Friedrich, CEO of Dürr Systems AG.

Logistics within the paint shop are handled by Dürr’s EcoProFleet AGVs, which continuously transport bodies between workstations and a high-bay warehouse. Their movements are coordinated by DXQlogistics.control, a software solution that digitally manages material flow based on utilisation, equipment status and availability.

Digitalisation plays a central role in the facility. Solutions from Dürr’s DXQ product family transform the paint shop into a smart factory. The DXQcontrol manufacturing operations management (MOM) system, built on a microservices architecture, provides more than 50 functions covering planning, execution, monitoring, optimisation and predictive analysis. In addition, DXQanalyze enables data-driven insights such as predicting component service life and correlating quality results with specific process steps.

“Our goal at CEER is to build a world-class manufacturing facility, setting new benchmark for efficiency and sustainability. This Paint Shop of the Future will place CEER at the forefront of automotive manufacturing innovation, allowing us to offer our customers in Saudi Arabia and the wider region a level of customization they have never seen before. The result will be a more environmentally friendly manufacturing process and the ability to offer customisation in car colors, finishing, and intricate details that will excite the public,” has added James DeLuca, CEO of CEER.