New widely applicable additives with effective wetting and anti-cratering as well as excellent flow and leveling properties

Evonik Coating Additives has developed two new wetting agents: TEGO® Wet 290 and TEGO® Wet 296. The polyether siloxane-based additives improve wetting and anti-cratering properties and enhance flow and leveling. Both can be used for various substrates like wood, plastic, and metal surfaces. The main areas of application are waterborne automotive OEM and wood coatings.

The two additives differ mainly in their composition: TEGO® Wet 290 consists of 100 percent polyether-modified siloxane and is therefore particularly suitable for formulations with requirements of low volatile content. TEGO® Wet 296 is a 52 percent solution of a polyether-modified siloxane in DPM (dipropyleneglycol-methyl-ether), which works well in low solids formulations such as waterborne automotive basecoats.

TEGO® Wet 290 and 296 for waterborne automotive OEM coatings

Due to their excellent flow and leveling properties, TEGO® Wet 290 and TEGO® Wet 296, are well suited for the automotive market, where the demand for glossy coatings with a unique color impression continues to grow. Each product feature effective wetting and anti-cratering and improve the flow and leveling of the coated surface.

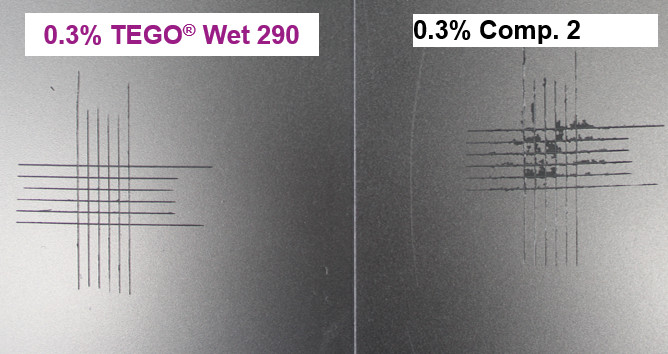

Beside highest optical requirements, the new substrate wetting additives contribute positively to adhesion properties. TEGO® Wet 290 clearly shows improved adhesion performance compared to competitor product.

Figure 1: Cross-cut of silver waterborne base coat

Figure 1: Cross-cut of silver waterborne base coat

TEGO® Wet 296 for waterborne wood coatings

Manufacturers of wood coatings benefit from the excellent wood pore wetting which brings out the structure of the substrate particularly well, something that is very important to many end customers.

Figure 2: Comparison of wood pore wetting & foaming (left: blank; middle: TEGO® Wet 296; right: Competitor)

Figure 2: Comparison of wood pore wetting & foaming (left: blank; middle: TEGO® Wet 296; right: Competitor)

TEGO® Wet 296 key properties:

- Good wood pore wetting

- Minimal foam stabilization

- Reduction of static surface tension

- Good compatibility

- Excellent flow promotion

- Efficient crater prevention and elimination

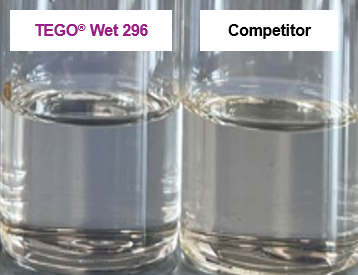

- Excellent transparency with no impact on coloristic of e.g., white coatings

Figure 3: Comparison of transparency (left: TEGO® Wet 296; right: Competitor)

Figure 3: Comparison of transparency (left: TEGO® Wet 296; right: Competitor)

More information about the two new wetting agents: TEGO® Wet 290 and TEGO® Wet 296

Find out more on

www.coatino.com!

On

COATINO® Campus we additionally offer a variety of trainings, lab videos and live event recordings with a focus on new, innovative products.