Pflaumer’s advanced crosslinker can deliver the long-term durability typically associated with solvent-borne isocyanates, while offering the formulation flexibility and environmental benefits of waterborne technologies.

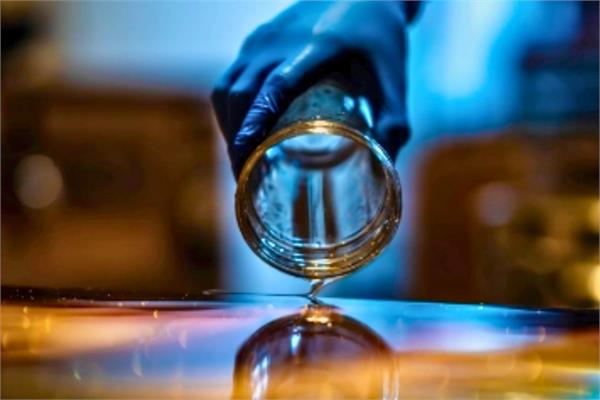

Pflaumer Brothers has recently introduced a next-generation aliphatic crosslinking agent designed for high-performance two-component (2K)

waterborne polyurethane systems.

TERACURE® HP-47 has been developed to meet the demanding performance requirements of sectors including industrial coatings, automotive, aerospace, OEM production, and construction. This technology is also intended to provide a performance advantage across a broad range of applications, including durable exterior coatings for metal or plastic substrates.

“TERACURE® HP-47 is a water-dispersible aliphatic polyisocyanate hardener that combines broad solvent compatibility with exceptional mechanical, chemical, and UV resistance. The product enables the creation of durable, flexible, high-gloss coatings that can withstand abrasion, weather, and harsh chemical environments. TERACURE® HP-47 delivers exceptional performance in applications for heavy-duty floor coatings, clear topcoats, and high-traffic surfaces,” has stated Brian Morris, Sales Development & Marketing Director at Pflaumer.

The hardener is compatible with a wide range of hydroxyl-functional polyols and provides excellent formulation control by allowing users to fine-tune the NCO to OH ratio. Formulations with higher NCO:OH ratios—typically above 1.0—enhance crosslink density, resulting in greater hardness, improved chemical and solvent resistance, and enhanced toughness. Ratios at or near 1.0 offer increased flexibility and impact resistance, making them well-suited for coatings on plastics, elastomers, and other flexible substrates.

Pflaumer notes that TERACURE® HP-47 must be used with polyurethane-grade solvents containing less than 0.05% water. Proper isocyanate handling procedures are required to achieve optimum performance in moisture-sensitive formulations. As with all high-performance chemicals, Pflaumer recommends validating TERACURE® HP-47 in its intended end-use environment prior to application.

Coatings formulated with TERACURE® HP-47 can incorporate a range of additives to optimise performance during and after application, including:

- Catalysts to accelerate curing under varying temperature and humidity conditions

- Wetting agents and dispersants to improve pigment stability and gloss

- Matting agents for satin or low-gloss finishes

- UV stabilisers to enhance outdoor durability

- Co-solvents to fine-tune clarity and curing behaviour

- Adhesion promoters for challenging substrates

About Pflaumer

Founded 91 years ago, Pflaumer manufactures specialty chemicals for coatings, inks, plastics, metalworking fluids, and lubricants, as well as supplying industries such as composites, electronics, and construction. The company produces polymers for high-performance coating applications, including epoxies, urethanes, polyureas, and polyaspartics.

Pflaumer continues to expand its portfolio with new technologies such as epoxy curing agents, specialty amines for polyaspartics and polyureas, aliphatic and aromatic polyisocyanates, urethane polyols, hydrogels, engineered colourants, functional additives, reactive and non-reactive diluents, catalysts, and moisture scavengers. Product development is supported by substantial pilot-scale manufacturing at the company’s Ewing, New Jersey headquarters and applications laboratories in New Jersey and California.