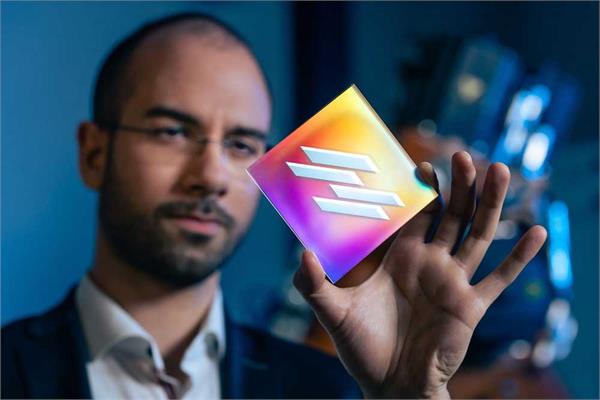

Dresden-based start-up Fusion Bionic, a spin-off from the Fraunhofer Institute for Material and Beam Technology IWS, developed a technology which allows to incorporate nano- and microstructures into surfaces in an instant using lasers.

A new technology for laser structuring is being developed and marketed by Fusion Bionic, a start-up and spin-off of the Fraunhofer Institute for Material and Beam Technology IWS.

This new technology opens up to several new possibilities, as product surfaces can be enhanced with all kinds of different effects, including the lotus effect, which uses a microstructure to allow any dirt that might stick to the surface to wash away the next time it rains; or the shark skin effect, which improves the dynamics of air and water on the outside of airplanes and ships, thus saving fuel.

Until now, these effects have been developed by coating or applying a film to the surface into which the microstructures are incorporated. The new technology, called Direct Laser Interference Patterning (DLIP) and developed by researchers at Fraunhofer IWS and Technische Universität Dresden, is an alternative, market-ready method of

permanently applying nano- and microstructures directly into the surface

using a laser in order to create biomimetic effects.

The process is quick and can currently handle up to one square meter of surface per minute.

“For a long time, lasers were much too slow to be used for finishing surfaces with large areas compared to coating or applying films,” says Managing Director of Fusion Bionic, Dr. Tim Kunze, who founded the company together with three partners. “But with the DLIP process we’ve made the leap to processing large surface areas quickly.”

How DLIP works

The DLIP process splits a single laser beam into multiple clusters of beams. To apply a pattern to the surface, these multiple laser beams are superimposed in a controlled way to create what is known as an interference pattern. This pattern can be distributed over a wider area, allowing surfaces with large areas to be processed rapidly.

The principle of interference

Light is transmitted in waves. When two beams of light are superimposed, their wave troughs and crests can cancel each other out or reinforce each other. Where light hits the surface, the laser energy removes or alters part of the material. The dark areas remain unaffected. “This allows us to create virtually any structure imaginable,” says Tim Kunze. “Lotus effects, shark skin, moth eyes and many more.”

How the DLIP technology came to be

The initial push to develop DLIP came around a decade ago from laser expert Prof. Andrés Fabián Lasagni when he moved from Saarland University to Fraunhofer IWS and shifted his focus to technology.

Lasagni, who is now Professor for Large Area Laser Based Surface Structuring at TU Dresden, saw great potential within this field and formed a highly skilled team during his time at Fraunhofer IWS, which has continued to grow under his successor Tim Kunze since 2017.

Building on Lasagni’s ground-breaking preliminary work, the two of them developed DLIP heads for industrial use that have since been installed by a number of pilot customers around the world.

With the help of the AHEAD program, a spin-off support program of the Fraunhofer-Gesellschaft, Dr. Sabri Alamri, Laura Kunze, Dr. Tim Kunze and Benjamin Krupop founded Fusion Bionic, which is now working with the support of its investor, Avantgarde Labs Ventures, on a forecasting platform using artificial intelligence, intended to be used to develop advanced laser functionalities.

In parallel, an AI test bench is being built at Fraunhofer IWS. This is a multi-sensor laser processing test bench that uses artificial intelligence to quickly predict and create the optimum surface structure for any problem.