Evonik Coating Additives has developed a new flow and levelling agent for solvent-borne clear coatings. TEGO® Flow 380 is a very compatible levelling agent with outstanding flow promotion.

The automotive industry constantly requests better and better appearance of their clear coatings. Creating additional challenges to this end are faster curing process and thinner dry film thickness. TEGO® Flow 380 dramatically decreases the dry film long-wave defects with the added benefit of anti-popping without compromising re-coatability. Based on a unique polymer technology, this new levelling agent is applicable for various clear coat formulations, particularly for automotive and transportation coatings.

TEGO® Flow 380 provides excellent levelling improvement in automotive OEM and refinish clear coatings

1) Leveling performance in both 2K and 1K automotive OEM clear coat

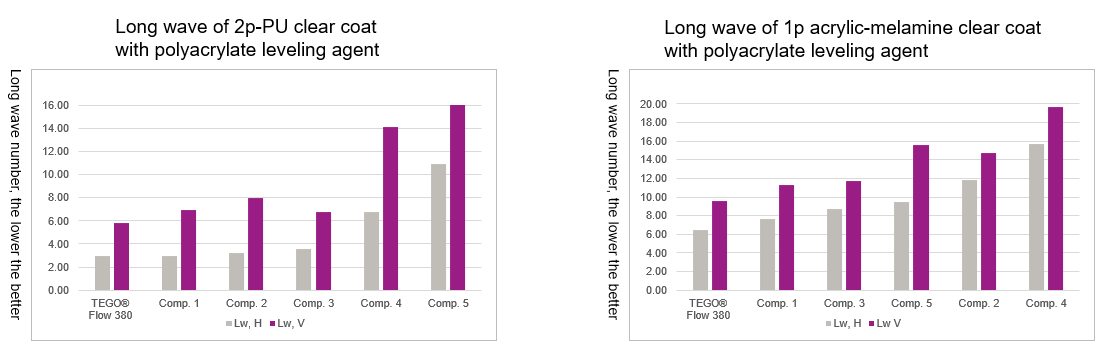

Comparison of long wave results in 2K and 1K automotive OEM clear coat.

Comparison of long wave results in 2K and 1K automotive OEM clear coat.

In above charts, TEGO® Flow 380 shows the lowest long-wave numbers, which reflect the best levelling performance in both 2K-PU and 1K acrylic-melamine clear coats, compared to all benchmarks. All additives are evaluated at the same dosage (0.3% active on total formulation) and the same dry film thickness (40 µm).

2) Levelling in 2K-PU automotive refinish clear coat

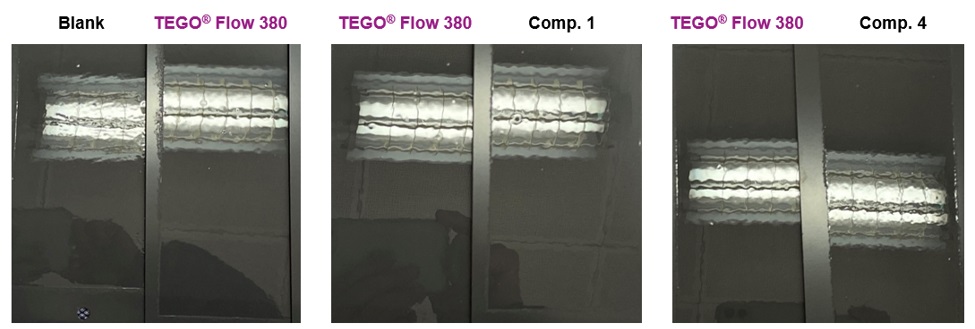

Levelling pictures in 2K-PU automotive refinish clear coat.

Levelling pictures in 2K-PU automotive refinish clear coat.

By observing the reflected image of the light fixture on the dry film in the above images, we can see TEGO® Flow 380 shows the crispest reflection. This illustrates the best levelling effect among the competitor grades in this 2K-PU automotive refinish clear coat formulation. All additives are compared at the same conditions of 40 µm dry film thickness and dosage of 0.3% active on total formulation.

TEGO® Flow 380 shows outstanding anti-popping performance in 2K-PU automotive OEM clear coat

Automotive OEM coatings are usually cured at high temperatures e.g., 140⁰ C. Popping sometimes occurs due to the expansion of solvent trapped inside the film when heated to high temperatures during the curing process. Solvent escapes to the surface and, because the surface is already dried or semi-dried, the film surface does not recover completely. This will cause popping defects apparent in the dry film. This issue becomes more critical with wet-on-wet processes because more remaining solvents from underlying coating layers will expand and evaporate together with the clear coat. Therefore, anti-popping is a demand for automotive OEM coatings formulators.

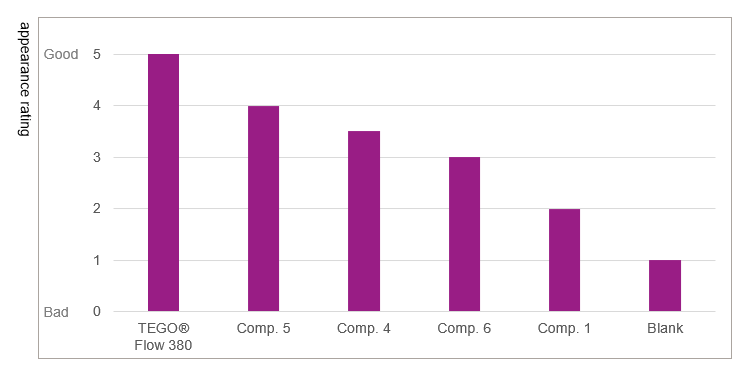

After applying a relatively thick coating film, popping defects can be detected by a visual check of the dry film surface. Rating of 5 is best (without any popping defects), and 0 the worst (with lots of popping defects).

Comparison of anti-popping results in 2K-PU automotive OEM clear coat.

Comparison of anti-popping results in 2K-PU automotive OEM clear coat.

Based on the above rating results, clear coats formulated with TEGO® Flow 380 show no popping issues while other samples have popping defects at same dry film thickness (80 µm) and same dosage (0.3% active on total formulation). TEGO® Flow 380 shows the best anti-popping performance compared to benchmarks. Along with its excellent leveling performance, TEGO® Flow 380 also imparts additional anti-popping effect. This brings more freedom to the coating formulators.

TEGO® Flow 380 also shows excellent re-coatability in 2K-PU automotive OEM clear coat

Re-coatability is crucial for automotive OEM coatings. Although the recoating ratio is rather low in an automotive painting production line, all additives and also other ingredients in the formulation definitely allow the recoating due to either coating film drawbacks or overbaking caused by emergent power cut.

Based on cross-cut testing results, the coating with TEGO® Flow 380 shows good recoating adhesion, meaning excellent re-coatability.

Our new TEGO® Flow 380 offers several essential advantages to our customers:

• Outstanding flow promotion

• Levelling improvement compared with anti-popping properties

• Excellent re-coatability

• Suitable for solvent-borne clear coatings

• Easy to handle without predilution

• Low VOC, non-dangerous goods