Delta Tecnic

recommends the use of masterbatch incorporating additives to prevent degradation of the polymers exposed to the sun and an appropriate selection of pigments to minimise long term discolouration of cables.

The environment has a negative influence on the service life of cables, as the incidence of sunlight, temperature cycles and humidity cause weathering. To avoid degradation and discolouration and the loss of the mechanical properties of polymers, Delta Tecnic can provide a series of masterbatch solutions to protect cables exposed to outdoor conditions.

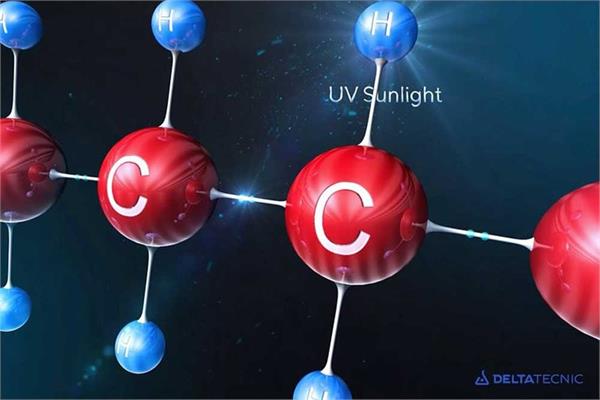

What is photodegradation

Photodegradation is a photochemical process produced by sunlight that is cumulative (meaning that it worsens over time) and irreversible. The degradation of the polymer by ultraviolet (UV) radiation influences the physical properties and thus its life expectancy.

Thus, UV radiation causes a photooxidative degradation that results in the breakage of the polymer chains, producing free radicals, which initiate a chain reaction of polymer chain breakage, leading to the deterioration of their mechanical properties. Consequently, there is a degradation of the visual appearance, gloss, and surface, as well as a loss of the mechanical properties of the cable, which limits its useful life in optimal conditions.

It should be remembered that when a plastic is exposed to solar and climatic conditions, there are two independent phenomena: polymeric degradation and photodegradation of the chromophore groups present in the pigments, which is responsible for the final colour of the cable.

How to prevent polymeric photodegradation

There are three ways to mitigate polymeric photodegradation:

- Use additives called UV filters that have the ability to absorb the ultraviolet light that causes degradation. Thus, when sunlight meets these additives, they react and prevent it from reaching the polymer, as if it were a sunshade.

- Through HALS (Hindered Amine Light Stabilizer), this family of additives reacts to free radicals, blocks them, and prevents the initiation of polymer chain breakage. When UV light strikes and the free radical is generated, HALS acts to stop the polymer degradation process.

- With black pigment (carbon black). The high absorption capacity of carbon black of UV radiation of light acts as a trap for this energy, preventing it from reacting with the polymer. The most effective grades are those of smaller particle size, as they have a larger surface area to trap solar radiation.

How to predict the behaviour of an outdoor cable

To develop functional, specific colour and additive masterbatches designed to cover the technical needs of the various cable industry applications, Delta Tecnic measures the behaviour of pigments outdoors in its laboratory through the Sun Test, which accelerates the state of exposure of plastics to different sunlight conditions thanks to an instrument that emits visible sunlight and cycles through changes in temperature, humidity, and dryness.

Thanks to Sun Test's laboratory trials with the different compounds used in the cable industry and with a multitude of pigments, it is possible to determine the optimum formulations to meet the most demanding requirements of cable regulations: by knowing what kind of behaviour to expect from outdoor cables, it is possible to accurately select pigments and thus predict the life expectancy of the plastic. This contributes to the installation of solid cable capable of withstanding both weathering and lightfastness conditions.