The British Coatings Federation latest report shows higher raw material prices, energy and freight costs hitting decorative paint and industrial coatings manufacturers hard.

In recent weeks, a new wave of higher raw material prices has hit the decorative paint and industrial coatings industry with increased energy and freight costs, and growing concerns about the war in Ukraine and the direction of the world economy, reports the British Coatings Federation (BCF).

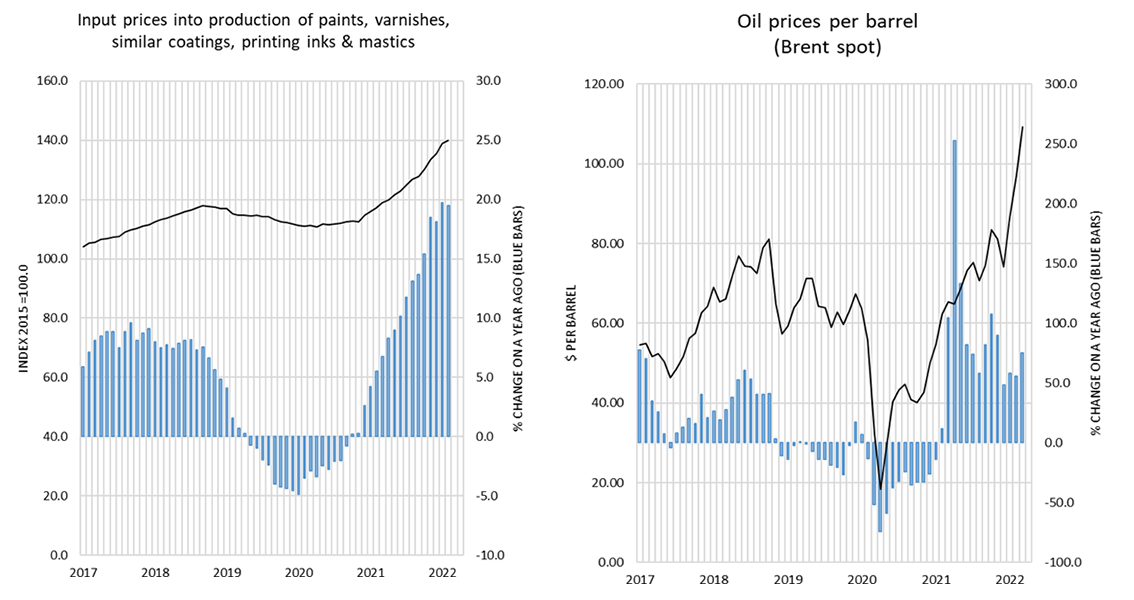

According to the ONS, raw material prices in the paint sector are now up 20% in February compared with a year ago, while many critical raw materials are up by more than three times this level or more.

As of March 29, Brent spot prices were up 75% on a year ago with materials such as N-Butanol and Xylene, for example, showing similar increases. Elsewhere, higher prices were seen for resins and related materials with Epoxy Resin prices up 110% in the last year and Nitrocellulose prices 40% higher.

For pigments, prices increased in most areas with Titanium Dioxide 22% higher in January at a new high of £2,836 per tonne. Packaging prices were also sharply higher in recent months with, for example, 2.5 litre round tins seeing an increase of 44% and with plastic containers up by a similar amount.

“All this is before further price announcements in recent days come into effect with many suppliers also imposing surcharges and force majeure in some cases. Inevitably, this means higher prices and with inflation now impacting on both business and consumer confidence this will further dampen demand in general over the next year. Tighter household and business budgets are also expected to see priority concentrated on essential areas of expenditure”, reports the BCF.

Much higher energy costs are also having a major impact on the industry.

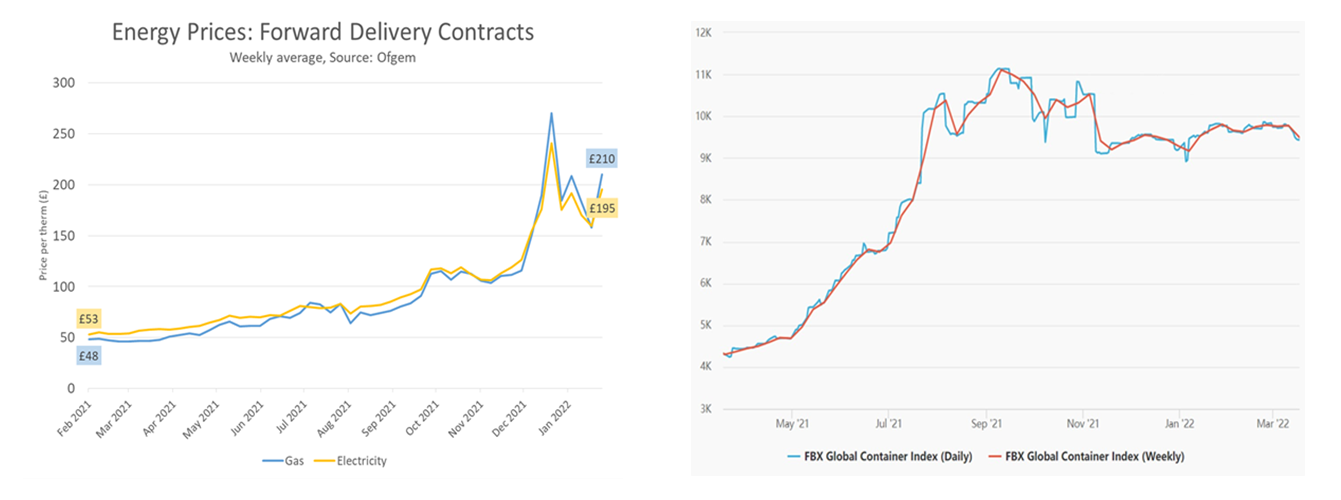

Figures from Ofgem show gas prices per therm at £210 in January this year up from just $48 at the start of 2021 and with similar increases being seen for electricity prices. Member companies are also reporting plenty of cases where suppliers have applied energy surcharges in recent weeks.

Supply issues relating to the availability for many raw materials are also a major concern for all firms. This has been the case since the easing of Covid-19 restrictions earlier last year but the situation is worsened by higher freight costs, which have more than doubled since this time last year.

Last but not least, the situation in Ukraine is disrupting global markets in multiple areas. In addition to the dreadful humanitarian costs of the war, this situation is having an impact on the supply chain, as well. For instance, with Russia and Ukraine being major sunflower oil growers the war is now having a knock-on effect in alkyd resins. Moreover, many minerals come from Russia some of which cannot easily be substituted while export routes by land through Russia are also being disrupted.

In China, a new wave of further Covid-19 lockdowns is further reducing feedstocks available for the European market.