By reducing the need for fresh air intake to just 5%, the Puebla plant maximises recirculation and cuts energy consumption in the spray booth by more than 60% compared with conventional wet scrubbing methods.

The global engineering company Dürr has delivered a new turnkey paint shop designed to significantly cut CO₂ emissions at one of Volkswagen Group’s largest production sites. The facility, located in Puebla (Mexico), was officially opened in January 2025.

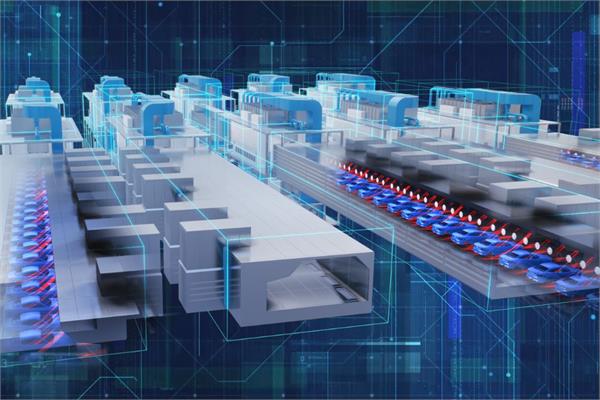

The project comprises two identical painting lines, equipped with fully electrified systems such as the EcoInCure electric drying oven. Dürr has also integrated core elements of its ‘Paint Shop of the Future’ concept, including a central high-bay warehouse and driverless transport technology.

Since its inauguration, the Puebla plant has been painting 90 vehicle bodies per hour across a range of Volkswagen models. The contract, awarded in 2022, was designed with flexibility in mind to accommodate future models and technologies. This adaptability is enabled by Dürr’s EcoProFleet driverless transport system, which works in tandem with the high-bay warehouse and is managed by the company’s DXQ software. The automated guided vehicles (AGVs) sort bodies predictively and deliver them to the correct workstation with pinpoint accuracy.

By breaking away from rigid production lines, Dürr’s modular approach shortens the overall process and ensures each body spends exactly the right amount of time at each stage. This individualised processing plays a major role in reducing CO₂ emissions. The two lines are equipped with 170 sealing and painting robots, along with application systems designed to handle multiple models.

Among these is EcoRS Clean F, which combines a feather roller cleaning system with robotic flexibility to cope with a wide range of body styles and contours. Dürr has also supplied the complete paint and PVC delivery systems, as well as AI-driven software from its DXQ suite.

As body drying is the most energy-intensive stage of the painting process, Volkswagen opted for Dürr’s EcoInCure electric drying system. Running on renewable electricity reduces overall CO₂ emissions by around 40% compared with conventional gas-fired paint shops.

“This was one of the reasons why Volkswagen opted for the EcoInCure electric drying system. Another is its special air duct system that heats the bodies from the inside out. This technology results in more uniform heating and cooling behaviour and reaches solid body components like the rocker panels more directly than conventional systems, cutting the body heating times by 30 percent,” has stated Bruno Welsch, COO Automotive at Dürr.

Dürr is the only supplier currently offering a combined package linking an electric oven with an electric air pollution control unit. Its Oxi.X.RV aftertreatment system purifies exhaust air via regenerative thermal oxidation without the use of an open flame. The process produces no additional CO₂, is highly energy-efficient, and can operate autothermally even with low solvent loads by reusing the heat generated during oxidation.

In addition, Dürr has installed its EcoDryScrubber overspray separation system, which uses limestone powder as a natural binding agent and HEPA12 filters to capture all particles from the process air. The saturated powder is automatically removed through a piping system without interrupting operations.