At parts2clean 2025, these cutting-edge cleaning technologies will be presented, highlighting their role in achieving sustainable, efficient, and high-quality hydrogen systems.

At parts2clean 2025, taking place from 7th to 9th October, hydrogen technologies

are gaining recognition as a cornerstone of emission-free mobility and the wider energy transition. At the heart of these systems are bipolar plates, which form the core of fuel cells and electrolyser stacks. These plates, made up of an anode and cathode separated by a proton-conducting foil, are produced from a variety of materials, including coated metal, graphite, and graphite–polymer compounds.

Metal bipolar plates are particularly promising, offering advantages in terms of light weight, compact design, and reliable cold-start performance. They also present potential for cost-efficient mass production, which could be further optimised through economies of scale. Within stacks, bipolar plates physically and electrically connect the anode of one cell to the cathode of the next. Utilising integrated flow fields, the plates manage the supply of reaction gases – hydrogen at the anode, oxygen at the cathode – while also regulating stack temperature, releasing water vapour, and handling thermal and electrical energy. “How efficiently they fulfil these multifunctional tasks determines the overall performance of a hydrogen system,” experts note.

The production of bipolar plates involves multiple stages, including unwinding the delicate raw material, forming anode and cathode plates, cutting, coating, and assembly. Contaminants can enter at any stage, from residual rolling and drawing greases to particulate matter such as burrs, chips, fibres, dust, oils, emulsions, smoke, and oxides. Any residue can impair plate quality, reduce efficiency, or shorten service life, making cleaning a vital step before joining and coating. A particular challenge is the removal of invisible chemical-film residues, whose composition is often unknown, while high-speed manufacturing necessitates rapid cleaning processes.

A range of cleaning methods is available, including wet chemical cleaning with solvents or water-based media, laser cleaning, steam and CO₂ snow jet cleaning, plasma cleaning, and hydro-cleaning. These can be used individually or in combination, depending on the material, type of contamination, and cleaning requirements.

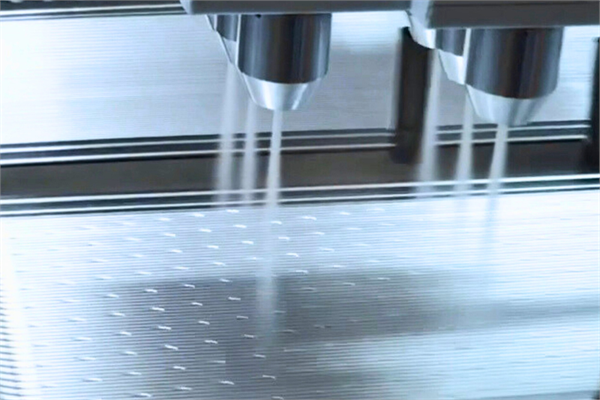

Wet-chemical cleaning remains widely used for oils, greases, and particles, though water-based processes often demand high energy for drying and extend cycle times. Steam blasting achieves excellent results in very short times for filmic-chemical and particulate contamination, smoke, and oxides. Hydro-cleaning, meanwhile, applies cleaning media via nozzles at defined pressures and temperatures, proving equally effective.

Dry CO₂ snow jet cleaning, using liquid carbon dioxide, can remove sludge, oxides, chemical-film contaminants, and particles quickly and selectively. High-pressure CO₂ blasting, operating at pressures up to 4,000 bar, also shows strong promise.

Ecoclean

is showcasing its new EcoCvolta, a continuous cleaning system for bipolar plates that integrates spraying, steam, hydro, plasma, CO₂ snow blasting, and drying. “The special design of the transport system ensures that the sensitive bipolar plates are handled gently,” has commented the company.

SLCR Lasertechnik has developed an automated solution that combines surface structuring and laser cleaning of bipolar plates. Using thermal and photochemical effects, the laser removes oxides, smoke, particles, and organic residues while roughening the surface to enhance coating adhesion. The process is fully automated, including processing on both sides of the plate, and reduces throughput times by performing laser cleaning immediately after structuring. “The micro- and nanostructures created increase the specific surface area, which leads to better mechanical anchoring of the coating,” has noted the company.