Quality Painting, an Italian company specialising in the industrial painting, screen printing, and the assembly of plastic components, has taken a significant step forward by investing in a coating robot equipped with VR tracking technology. This innovative solution, developed by CMA Robotics, has optimised its production process by ensuring more precise, uniform, and repeatable finishes, while also overcoming one of the challenges that many companies in the coating sector are facing.

In an industry where precision is paramount and every finish tells a story of quality and expertise, many businesses share a common challenge: finding specialised labour. In the industrial coating market, this shortage has become a genuinely critical issue, often forcing companies to rethink their processes deeply to ensure operational continuity, efficiency, and ever-higher quality standards.

“Training an expert coater can take months, if not years: an unsustainable timeframe in such a competitive and constantly evolving environment like ours,” says Filippo Di Pietro, founder and owner of Quality Painting, a company specialising in the coating, screen printing, and assembly of plastic components for industries where high quality is a key requirement, such as the automotive sector. “However, it is precisely from challenges that the most significant breakthroughs arise. To tackle this problem and, at the same time, optimise our finishing operations, we have recently decided to equip our coating department with a self-learning robot featuring VR tracking technology, supplied by CMA Robotics (Pavia di Udine, Udine, Italy).”

Next-generation robots, equipped with high-precision sensors, self-learning systems, and user-friendly interfaces, can replicate the movements of an experienced operator with remarkable accuracy, minimising errors and waste while ensuring greater consistency in results. “Moreover, the automation of the most repetitive and strenuous tasks, such as paint application, enables our operators to focus on higher-value tasks: finishing cycle supervision, robot programming, and quality control. This new robot is ideal for our needs, as it guarantees speed, precision, and uniformity. And unlike humans... it never gets tired,” adds Di Pietro. “This way, we can tackle the shortage of skilled labour with greater confidence, combining the expertise of our operators with the efficiency of automation. The result? Consistent and repeatable top-quality finishes.”

About Quality Painting

Founded in 2016 in Osimo (Ancona, Italy), Quality Painting has quickly established itself as a leading player in the coating of plastic materials for highly complex industries such as automotive, lighting, household appliances, furniture, HoReCA, footwear, and fashion. This achievement has been made possible by a rigorous technical approach, attention to aesthetic-functional details, and a well-structured internal organisation.

“The beating heart of the company is our team, composed of skilled professionals who are passionate and deeply committed to their work. It is thanks to their daily dedication that we have earned the trust of our customers,” explains Di Pietro. “Our in-house technical department constantly researches new solutions, materials, and treatments to provide the very best in terms of innovation, reliability, and customisation. At the same time, we pay great attention to the aesthetic appeal of end products, offering a wide range of colours and finishes tailored to the characteristics of each workpiece and the customer’s specifications.”

As proof of its commitment to excellence, Quality Painting is ISO 9001:2015 certified, demonstrating the adoption of a quality management system that meets the highest regulatory requirements. In addition to industrial coating, the company also offers polishing, assembly, and packaging services to ensure comprehensive support throughout the entire production chain.

A coating department designed for every production need

Quality Painting’s plant is equipped with two liquid coating systems designed to meet different production requirements. “The first is an automatic plant with a monorail conveyor that we use for wet-on-wet coating, ideal for mass-produced parts,” explains production manager Samuele Gatto. “The second was developed specifically for handling small batches and oversized parts. It is a static system consisting of a pressurised booth with a dry filtration unit, a robotic application station, and an adjacent drying oven. It is here that we have installed the new CMA Robotics robot, equipped with self-learning and VR tracking technology.”

More in detail, after being cleaned and pre-treated, the components are placed in the booth and positioned on specially designed racks, then loaded onto the robot’s carousel. By scanning the barcode on each part, the system automatically recognises the programme to be executed and starts the correct coating cycle, which generally includes primer, top coat, and clear coat application. Between one stage and the next, the racks with the workpieces are temporarily unloaded from the carousel for the flash-off time, and then reinserted to complete the cycle. Once the three coats have been applied, the components are taken to the baking oven, where they dwell for at least 1 hour at a controlled temperature. The process ends with rigorous quality controls, which are essential to meet the high standards required by customers, followed by packaging and shipping.

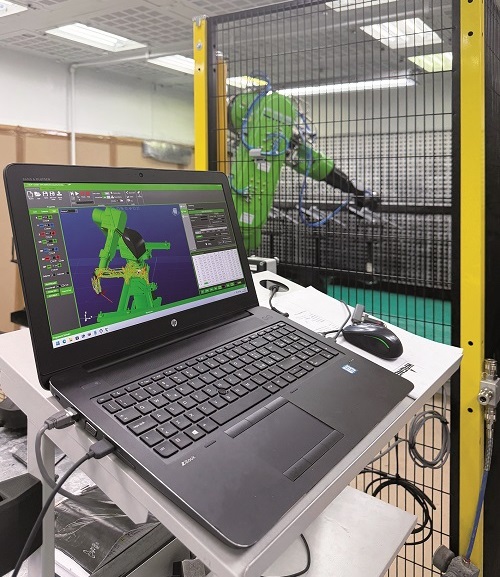

The self-learning coating robot supplied by CMA Robotics. © ipcm

The self-learning coating robot supplied by CMA Robotics. © ipcm

Technical features and functions of the new robot

Supplied by CMA Robotics and equipped with the latest generation VR tracking and self-learning technology, the new coating robot was installed in May 2025 with the aim of increasing productivity, simplifying cycle programming, and improving operational flexibility. “We opted for self-learning technology because we can leverage its potential to the fullest, thanks to our experience in the field. In just a few steps, we can configure the required movements, significantly reducing programming times and adapting the system even to complex and variable processes,” explains Samuele Gatto.

Marco Zanor, sales director at CMA Robotics, explains: “The VR tracking system is a breakthrough compared with traditional self-learning methods, which involved manual programming using a gun mounted directly on the robot’s arm: the operator physically moved the robot during the teaching phase, and the system recorded its trajectories. The new technology developed by CMA surpasses this approach by introducing a clear separation between the operator who draws the trajectory, the software suite, and the robot’s mechanical parts. As a result, the coater operates independently through the software interface, without having to work directly on the machine. This simplifies programming, speeds up configuration times, and improves work ergonomics.”

The software suite for cycle programming. © ipcm

The software suite for cycle programming. © ipcm The robot’s electrical panel. © ipcm

The robot’s electrical panel. © ipcmThe system uses high-precision sensors connected to a joystick on which a gun is mounted. During the manual coating of the first workpiece, the sensors detect the gun’s position in Cartesian space in real-time and automatically generate a coating programme, also calculating the robot’s joint dimensions to replicate the cycle on all other components. A ring equipped with an infrared tracker constantly detects the position of the gun, while visual and acoustic signals alert the operator if they perform a non-replicable movement or approach the limits of the working area. This allows for a more natural operation, eliminating the need to connect the gun to the robotic arm and to have the robot physically available during the teaching phase. The software suite, which can be used on any computer, even remotely, stores trajectories and modifications quickly and efficiently, and any adjustments can be made via simulation without interrupting production.

“Another innovative feature offered by CMA Robotics is the automatic mixing system integrated directly onto the robot arm, with gear pumps and valves for colour change, which conveys the paint products from the management units to the application point. Although already widespread in the automotive sector, this is a novelty for coating contractors, which typically use centralised and separate units. Finally, this system can also be integrated into other applications on customer request,” states Zanor.

Improved productivity, quality, and result repeatability through automation

Investing in this new CMA Robotics robot was a real turning point for Quality Painting: “It ensures production continuity, consistent quality, and maximum repeatability,” explains Di Pietro. “We have overcome the difficulty of finding qualified operators while maintaining a stable workforce of 16 people. In addition, automation has reduced waste and residues, with significant savings on materials and disposal operations, and has optimised polishing times and costs by eliminating the imperfections typical of manual coating.”

“The robot works with great precision thanks to the use of dedicated racks and to weekly planning that reduces downtime and increases efficiency,” notes Gatto. “One of its strengths is the automatic mixing system integrated on the robotic arm, which accurately doses the paint and catalyst by synchronising perfectly with the work cycle. The result is a uniform, flawless finish with minimal waste. The impact on our production process was immediate: thanks to the new robot, Quality Painting has consolidated its position on the domestic market, recording significant growth in turnover and attracting more important customers.”

“This positive experience with CMA Robotics encourages us to invest even more decisively in technology and innovation,” concludes Di Pietro. “We aim to strengthen our presence in a dynamic market and grow further thanks to an increasingly future-oriented approach. We are looking ahead with confidence, ready to implement further solutions to respond effectively to market and customer needs while maintaining high quality standards and maximising production efficiency – because quality is not only in our name but the heart of every process.”