How much can technical advice from a partner with in-depth coating expertise influence paint performance? At Newton Trasformatori, the specialist support offered by Sherwin-Williams, the long-standing supplier of coatings to this Tuscany-based manufacturer of transformers for electrical power management, has proved strategic in optimising coating cycles and achieving the high degree of corrosion protection performance required for its devices intended for C4 and C5-M environments.

A transformer is a static electrical device that operates on alternating current, based on the principle of electromagnetic induction. Its purpose is to transfer electrical power between two separate circuits through inductive coupling, modifying voltage and current but keeping the frequency constant. This ability to transform electrical energy makes the transformer a crucial component in any power generation, transmission, and distribution system.

Despite sharing the same operating principle, these devices come in a wide variety of sizes, from tiny signal transformers used in electronic and audio equipment to massive units weighing hundreds of tonnes, used in substations to interconnect portions of national grids or power large industrial plants. Although the introduction of new technologies has led to a reduced use of traditional transformers in specific sectors, these devices remain vital for alternating current management, particularly in long-distance transmission, which requires high voltages. At the same time, with the ever-increasing demands related to the energy transition and widespread electrification, amplified by the requirements of rail traction, data centres, electric vehicles, and renewable energies, there is a growing need for direct current solutions, with more compact high-frequency transformers integrated into advanced power systems.

Newton Trasformatori SpA (Poggibonsi, Siena, Italy) has been specialising in the design and manufacture of distribution and power transformers for complex applications, even in extreme conditions, for over forty years. “Our company has developed hand in hand with the evolution and expansion of the national and international electricity grid,” says Lorenzo Zoncada, Process and Plant Engineering Manager at Newton, “so much so that today our customers include leading companies such as Sonepar, ABB, Enel, Enel Romania, Endesa, Ferrovie dello Stato Italiane, ENI-Saipem, RFI, Jepco (Jordan), and Hitech (Russia), to name but a few.”

This Tuscan company designs transformers for completely exposed structures that are subject to thermal shocks, aggressive atmospheric agents, pollutants, and salt and for which surface protection plays a strategic role. To guarantee the durability of their components, it uses ISO 12944-compliant, class C4 and C5-M protective coatings that ensure outstanding performance even in highly corrosive environments. To this end, it has always relied on Sherwin-Williams water-based paint products.

“Until a few years ago, for the surface coating of the casings and other components of our transformers, we only used a dip coating plant supplemented by a manual application booth. However, due to increasing demands and growing production volumes, we decided to upgrade our coating department by adding a new line that integrates the most innovative systems and devices available on the market: a plant from Savim Europe (Arbizzano, Verona, Italy), a conveyor from CM Automazione (Giussano, Monza e Brianza, Italy), two booths with articulated robots from Lesta (Dairago, Milan, Italy), and a paint management unit and application equipment from Wagner. We also reviewed and updated our entire coating process in partnership with the Sherwin-Williams team in Tuscany and Protek, a distributor of Wagner devices, to optimise our application cycle and achieve higher uniformity, greater paint adhesion, and overall better results.”

Power management with Newton's transformers

To understand the strategic role of transformers in managing the electrical grid, an overview of the energy distribution structure itself can be helpful. “Electricity,” explains Zoncada, “is transmitted over long distances at high voltage to minimise energy losses. In Italy, for example, high-voltage lines operate at very high values. At the entrance to built-up areas, the voltage undergoes an initial transformation through large power transformers, which generally reduce it to 15,000 to 20,000 volts (medium voltage). This energy, which is not yet directly usable by consumers, is then distributed within the urban and industrial areas, where a second set of equipment comes into play: distribution transformers. These devices carry out the final stage of the process, reducing the voltage to 220 or 400 volts, i.e. values compatible with domestic and commercial use.”

Newton Trasformatori’s entry into the mega transformer sector is the most recent and advanced milestone in an industrial journey that began over forty years ago. This segment, which is constantly growing, now accounts for approximately 5% of the company’s total production. Distribution transformers, a sector in which Newton has gained extensive experience and consolidated its market position, still account for the remaining 95%.

“This firm was founded in 1982 in a factory of just over 500 m². Thanks to the work of its highly specialised team led by our current president Guglielmo Montagnani, its professionalism, flexibility, and customer focus as well as the use of advanced design methods and dedication to meeting commitments, Newton quickly grew from a small artisan business to a major industrial enterprise covering 20,000 m², up to becoming a key player in the national and international markets.” While remaining a family-run company, Newton has recently begun a transition process between the second and third generations, with the latter still too young to join the company, by relying on a management team composed of Stefano Moretti (CEO) and Samuele Paiusco (COO) and adopting a matrix-type organisational structure.

The build quality of Newton’s transformers

Newton designs and manufactures high-efficiency transformers aimed at optimising energy performance and meeting more sustainable distribution requirements. “We have built our identity on proven technical expertise, compliance with regulations, high-quality production processes, and a constant focus on technological innovation. Current production stands at approximately 5,000 transformers per year, categorised by type and destined for numerous countries worldwide. A forward-looking vision guides us: new technologies and solutions are already at an advanced stage of development, enabling us to respond to a constantly evolving market. This approach also forms the basis for our new collaboration with Ferrovie dello Stato, which is set to commence in 2026 for the supply of transformers intended for Italy’s national railway infrastructure.”

Indeed, Newton Trasformatori demonstrates its technical expertise and production flexibility in the design of transformers for major utility companies such as Enel. “We state, verify, and document every parameter – from insulation class to coating, from the use of natural esters as a dielectric fluid to voltage regulation solutions – in accordance with extremely detailed global specifications; especially in this sector, there is no margin for unjustified deviations.”

The reliability of Newton’s transformers is guaranteed not only by their design but also by their ability to withstand particularly harsh environmental conditions, such as low Arctic temperatures (down to -60 °C) or sandstorms in desert environments. These challenges necessarily impose high standards, especially in terms of surface treatment and corrosion protection. “Since we insourced our coating operations about thirty years ago, on specific parts such as casings, we have been applying a protective layer of approximately 90 µm in one coat by immersing them in a tank filled with a Sherwin-Williams grey one-component, acrylic top coat. With the subsequent introduction of a new colour, green, we have also implemented a two-coat cycle in a manual booth using airless application technology. In 2023, when we designed a new robotic system for components requiring higher thicknesses in collaboration with Savim Europe, we also transferred our coating expertise to this line.”

The coating of transformers

The production cycle of Newton’s transformers starts with metal sheets with varying thicknesses depending on the power and configuration of the equipment. Their casing design is also tailored to the specific thermal dissipation requirements: their overall dimensions can vary significantly depending on the power required, ranging from a cube measuring approximately 700x700 mm for the most compact models to a size of 1,200x1,200 mm for the largest ones. Metalworking, including laser cutting and welding, precedes the surface treatment phases, defined according to the technical specifications.

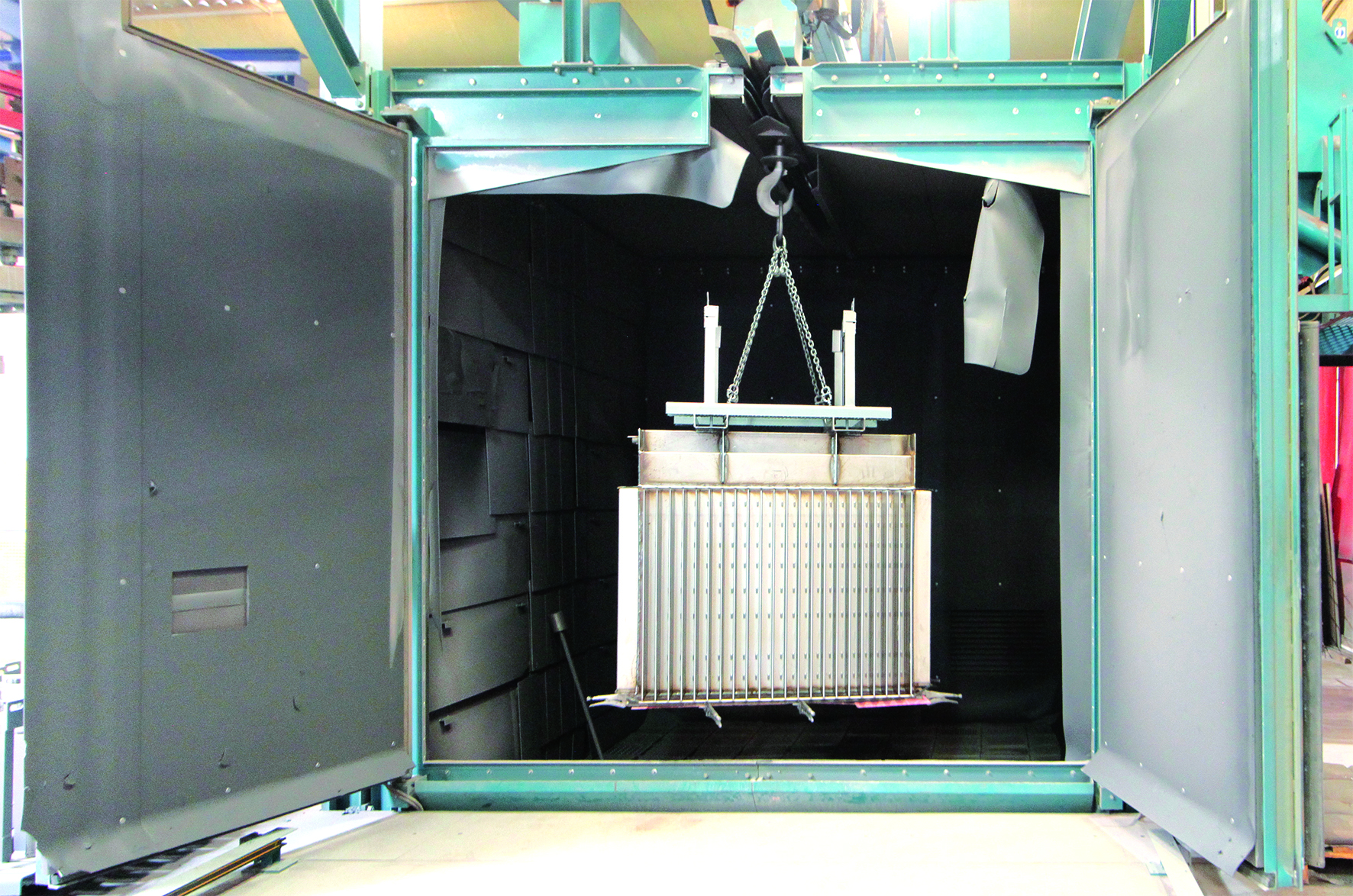

After sheet metal processing, the components are washed manually with a high-pressure jet, then shot-blasted in an automatic cluster system with four turbines from OMSG (Villa Cortese, Milan, Italy), and finally blown manually to remove any residues. “We are currently conducting tests with the OMSG team to add a specific product to the grit for further reducing dust residues and improving surface quality,” illustrates Zoncada. After pre-treatment, the parts enter the coating plant designed and installed by Savim Europe.

A casing inside the OMSG shot blasting machine.

A casing inside the OMSG shot blasting machine.“Initially,” Zoncada recalls, "the results were not satisfactory: we found numerous film defects such as burn marks, scratches, and overcoating. Moreover, when working with high thicknesses, it was difficult to achieve the 200-µm value required by specifications with a single application.” To address these critical issues, the company sought the advice of Lorenzo Mori, the Sherwin-Williams Company’s General Industrial Agent for Tuscany, Davide Aleotti, Senior Sales Manager - Central Italy GI EMEAI at Sherwin-Williams, and Roberto Martinelli from Protek Srl, a distributor of Wagner systems. “Thanks to their input,” concludes Zoncada, “we have integrated two robotic booths and replaced the airless guns with new AirCoat guns from Wagner, which combine airless technology with air support to ensure better film distension even with high thicknesses.”

“In the AirCoat system,” indicates Martinelli, “the nozzle atomises the material using the airless principle while surrounded by an air curtain, which makes the application process particularly effective. The low air consumption and the soft spray pattern generated by the air curtain allow for optimal results even at low pressures. This is the ideal solution for coating large surfaces on a high number of parts.”

The system designed by Savim thus consists of: a booth for applying the first coat, a flash-off tunnel equipped with an air burner sized for low temperatures, a booth for applying the second coat, and a final drying oven with a 6-metre pre-chamber; the line is complemented by skimmer supplied by Hydro Italia Srl (Medicina, Bologna, Italy) to treat the booths’ water curtains.

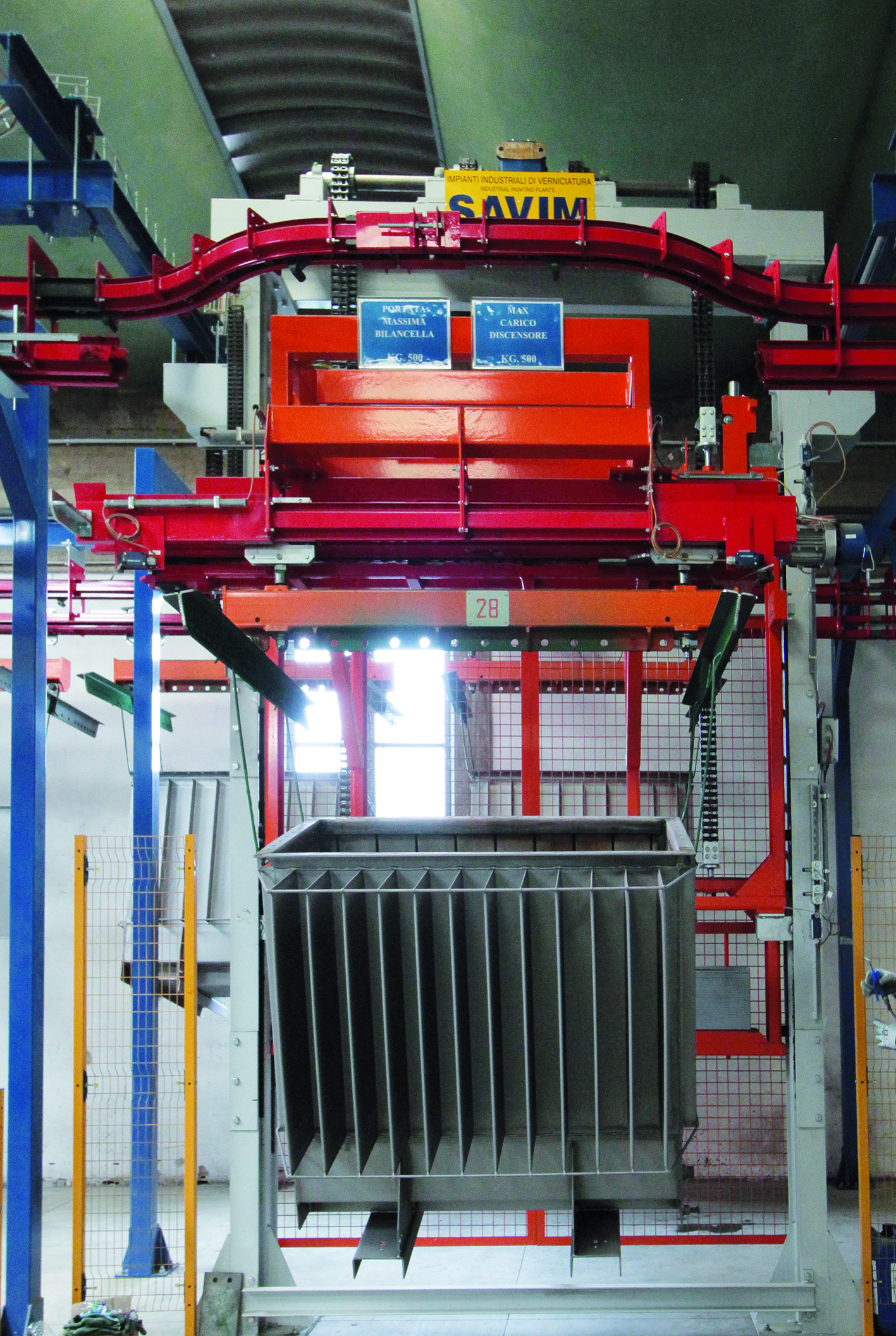

The Savim Europe coating plant is equipped with a CM Automazione power & free conveyor with 92 load bars, each with a maximum load capacity of 500 kg.

The Savim Europe coating plant is equipped with a CM Automazione power & free conveyor with 92 load bars, each with a maximum load capacity of 500 kg. The two coating booths side by side.

The two coating booths side by side.The search for the most suitable paint

“To provide the most suitable coating for these specific application requirements, Sherwin-Williams Research and Development team reformulated a previously approved product, creating a personalised solution for our long-standing customer Newton,” explains Davide Aleotti. “This has ensured not only the highest quality but also an added value in terms of attention, reliability, and care – a concrete commitment that reflects Sherwin-Williams closeness as a partner, always focused on building relationships of trust and offering tailor-made solutions (Table 1).”

Table 1: Data sheet of the product 42301 – F81GUI001 7593-FG AYW DTM 1K MATT GREEN 6002

Characteristics

|

|

Physical properties

|

|

Viscosity (D4/25 °C)(s)

|

60 – 90

|

Specific weight (theoretical) (kg/l)

|

1.24 ± 0.05

|

Solid content by weight (theoretical)

|

51.8 ± 2.0%

|

Solid content by volume (theoretical)

|

38.1 ± 2.0%

|

VOC (theoretical) (g/l)

|

71

|

Volatile components excluding water (theoretical)

|

5.8%

|

Water (theoretical)

|

42.4%

|

pH

|

7.9 – 8.5

|

Additional information

|

|

Application recommendations

|

|

Substrate/Pre-treatment

|

The surface to be coated must be free of oil, grease, and rust. Suitable pre-treatment is recommended for optimum performance.

|

Dilution

|

Depending on the application system

|

Film properties

|

|

Gloss (60 degrees)

|

20 – 30

|

Theoretical coverage @ 1 μm DFT m²/kg

|

326

|

Version

|

009 00

|

The benefits achieved

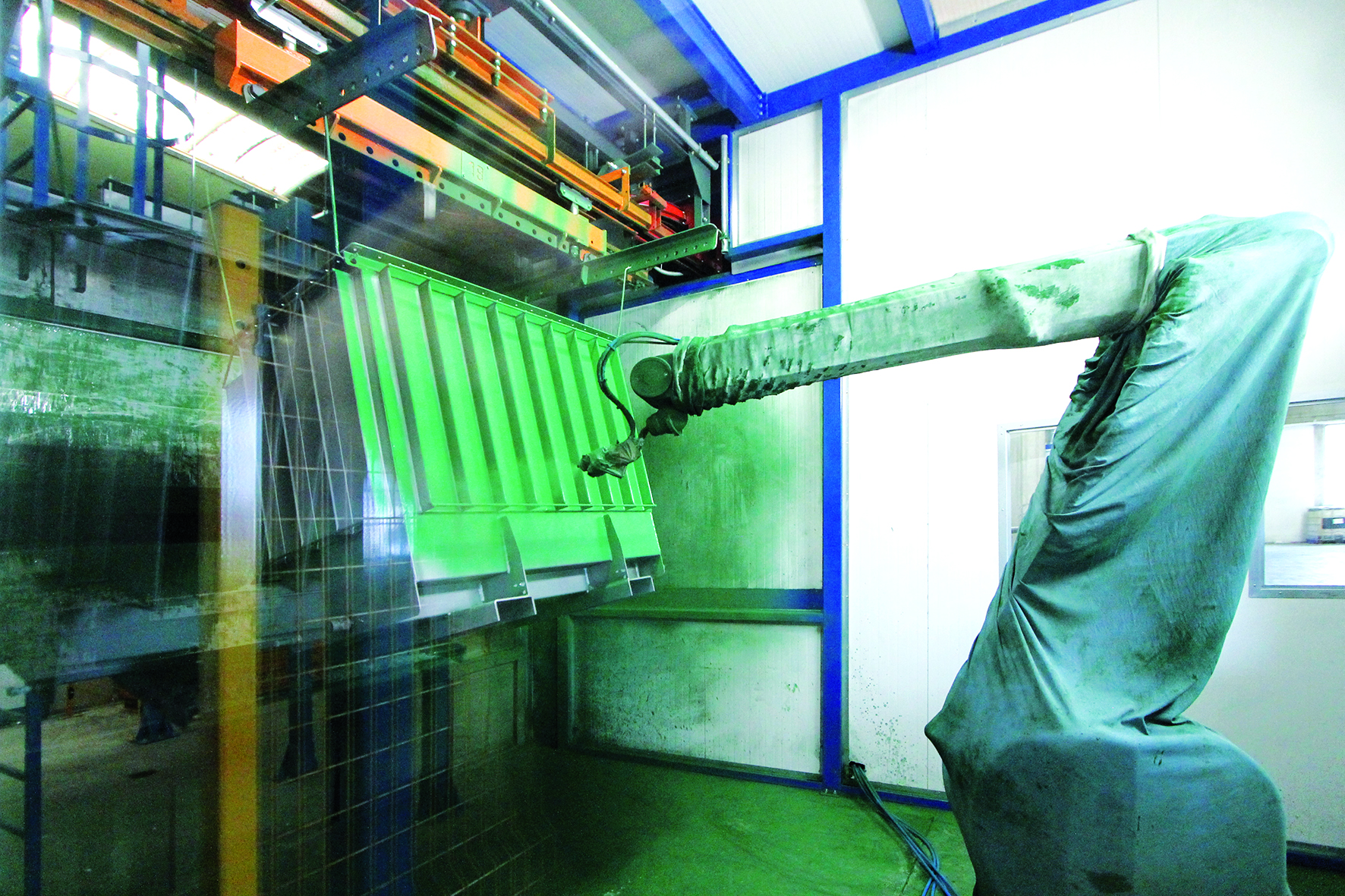

A Lesta articulated robot during the application of Sherwin-Williams paint.

A Lesta articulated robot during the application of Sherwin-Williams paint.“Thanks to the advice of our long-standing paint supplier Sherwin-Williams,” says Zoncada, “we are now able to achieve thicknesses of 200 µm – covering approximately 90% of our required applications – without the need for touch-ups after assembly. In the past, the inability to collect large components that needed retouching in a buffer forced us to send them to the assembly department and return them to the coating department for touch-ups only once assembled, with a considerable waste of time and logistic effort.” The new cycle, on the other hand, allows for the direct sending of the painted components to assembly and then to shipping, resulting in a significant improvement in efficiency and a substantial increase in production capacity.

“Currently, the power & free conveyor installed by CM Automazione operates with 70 load bars, each with a maximum load capacity of 500 kg,” notes Zoncada, “but the total capacity of the system can reach 92 load bars with approximately 250 metres of chain. The power & free system allows collecting the load bars in buffers, thus compacting the space required, as clearly demonstrated in the oven area. The loading and unloading area is served by an elevator that ensures safe and ergonomic operations. Rotation systems interfaced with the robots in the two booths also contribute to simplifying plant management, allowing for control in the required positions (0°–90°–180°–270°). The result is an optimal coating process, even on complex parts such as fins, which ensures uniform thicknesses of up to 250 µm and avoids the dripping and stress cracking problems that were frequent in the past. We have also reduced the oven dwelling time: one hour at 50 °C is now sufficient to completely dry the coating film.”

The Savim plant can treat casings up to approximately 1 m3.

The Savim plant can treat casings up to approximately 1 m3. The Wagner paint management unit.

The Wagner paint management unit. The skimmer supplied by Hydro Italia Srl to treat the booths’ water curtains.

The skimmer supplied by Hydro Italia Srl to treat the booths’ water curtains.Newton Trasformatori’s upcoming projects

In collaboration with Sherwin-Williams and Protek’s technicians, the Newton Trasformatori team is currently working on optimising the plant’s application parameters with particular attention to the robots’ speed, in order to define uniform settings for all fifteen types of products handled by the coating department. “The goal,” says Zoncada, “is to identify a stable configuration that allows us to paint our entire range of components, from casings to covers, while ensuring uniform results even among batches processed at different times.”

Simultaneously, Sherwin-Williams Research and Development team is developing a new grey paint formulation that has the same properties as the green one currently in use and can also be applied in the automatic line with a thickness of 90 µm. That will reduce the load on the dip coating system, increasing overall process efficiency. “This is yet another example of our partner’s ability to respond quickly to our needs,” states Zoncada, “as also demonstrated by the recent creation of a custom, two-component metallic paint designed to meet a specific request from one of our clients.”

The CM Automazione conveyor’s elevator in the loading and unloading station.

The CM Automazione conveyor’s elevator in the loading and unloading station. One of the types of transformers manufactured by Newton. Ⓒ Newton Trasformatori Spa

One of the types of transformers manufactured by Newton. Ⓒ Newton Trasformatori SpaThe energy challenge of the future increasingly hinges on the ability to anticipate the needs of new markets, from high frequency to direct current management and the choice of cutting-edge materials. Newton has chosen to invest in these areas by combining its consolidated experience with new technologies and skills, adopting a forward-looking approach in which its partnership with Sherwin-Williams marks a further step in a strategy aimed at offering reliable and increasingly high-performance solutions.

From left to right: Davide Aleotti from Sherwin-Williams, Roberto Martinelli from Protek, and Lorenzo Mori from Sherwin-Williams with Lorenzo Zoncada from Newton Trasformatori Spa and Alessia Venturi from ipcm®.

From left to right: Davide Aleotti from Sherwin-Williams, Roberto Martinelli from Protek, and Lorenzo Mori from Sherwin-Williams with Lorenzo Zoncada from Newton Trasformatori Spa and Alessia Venturi from ipcm®.