Cortec® continues to position corrosion protection as a practical and effective strategy for protecting assets, maintaining operational readiness, and improving industrial resilience in the face of unexpected events.

As global supply chains continue to face disruption from industrial accidents, natural disasters, and geopolitical uncertainty, corrosion protection is proving to be a critical risk-management tool for manufacturers. Events such as the September fire at an aluminium plant in New York have demonstrated how a single incident can trigger raw material shortages and force production shutdowns across multiple industries.

Cortec® Corporation is highlighting the role of corrosion protection in helping manufacturers minimise financial losses and protect valuable components during unexpected interruptions. When assembly lines come to a standstill, corrosion can quickly turn usable parts into scrap, compounding the damage caused by supply delays.

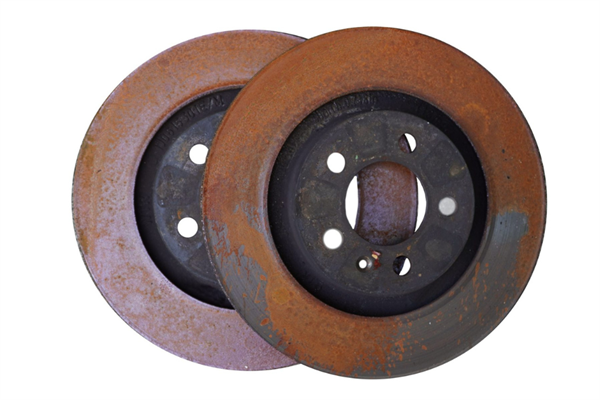

For automotive manufacturers and other industries that rely on metal components, preserving parts already on the production line is essential. Engines, panels, and precision assemblies must remain in install-ready condition until operations resume. Without protection, exposure to humidity and temperature changes during downtime can result in rust and surface degradation.

Cortec® offers a range of corrosion protection solutions designed specifically for these scenarios. Products such as Cortec® VpCI®-126 bags and VpCI® emitters, including BioPad®, release vapour phase corrosion inhibitors that form a protective molecular layer on metal surfaces inside enclosed packaging. With correct application, these solutions can provide up to two years of corrosion protection, helping manufacturers safely bridge extended supply chain disruptions.

Unlike traditional oil-based rust preventatives, Cortec® VpCI® technologies do not leave greasy residues. This allows components to be removed from packaging and installed immediately once production restarts, reducing both downtime and labour costs. For non-climate-controlled warehouses or outdoor storage, Cortec® also provides heavy-duty options such as VpCI®-126 HP UV Shrink Film, offering enhanced durability and environmental resistance.

Beyond short-term shutdown protection, Cortec® corrosion protection supports longer-term supply chain resilience. Manufacturers seeking to build reserves of critical raw materials can protect metal coils by applying vapour phase corrosion inhibitors to exposed edges and wrapping them in Cortec® VpCI® tubing. High-value electronic components, which have experienced repeated shortages in recent years, can be safeguarded against corrosion and electrostatic discharge using EcoSonic® VpCI®-125 HP Permanent ESD Bags.

Industrial catastrophes often affect not only the companies directly involved, but also customers and downstream suppliers. While physical damage from fires or natural disasters cannot be reversed, Cortec® corrosion protection technologies enable manufacturers to limit secondary losses by preserving parts, materials, and inventory during prolonged disruptions.