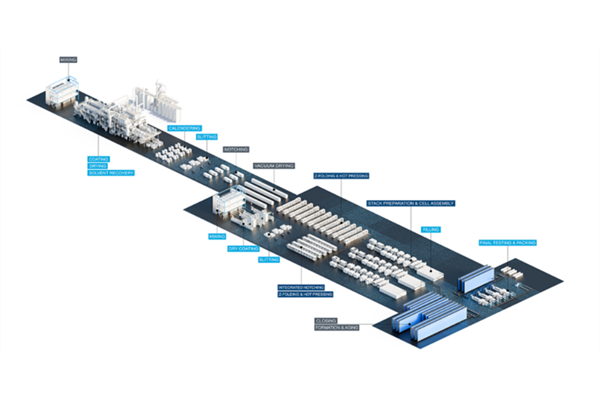

The lithium-ion battery cell production factory developed by Dürr and GROB enables a 50% reduction in space and energy consumption, thanks to groundbreaking dry coating and Z-folder technologies.

The engineering company Dürr, along with GROB, have jointly presented a pioneering concept factory for lithium-ion battery cell production that promises to halve both the required production space and energy consumption, while enhancing performance and quality. Dürr also introduced a new branding for its electrode coating and electrolyte filling systems under the name “X.Cellify”.

"The new concept factory combines a dry coating line with integrated Z-folder assembly. Our dry coating process significantly reduces both space and energy consumption by 50%, delivering much greater efficiency and lower operating costs for manufacturers,” has stated Jochen Weyrauch CEO of Dürr.

The concept, which debuted at The Battery Show Europe 2025 in Stuttgart (Germany), is built around cutting-edge technologies such as dry electrode coating and a compact, high-speed Z-folder cell assembly solution. As the event’s largest exhibitors, Dürr and GROB are showcasing innovations that aim to redefine standards in battery cell manufacturing. The collaboration between the two companies, initiated in 2022, has grown to encompass almost the entire value chain of battery cell production across Europe and North America.

“With our expanded range of high-availability systems, we now cover nearly the entire battery cell production process using our own technologies,” has added German Wankmiller, CEO of the GROB Group.

Replacing conventional slurry with dry-mixed active materials, the Activated Dry Electrode® process eliminates the need for drying and solvent recovery. The powder is pressed into a freestanding film, which is then laminated onto collector foil on both sides. This approach enhances material efficiency

as surplus film can be reintroduced into production. Moreover, it allows for better control of coating thickness and uses less force in lamination, avoiding foil deformation and improving downstream processing.

GROB’s latest generation of Z-folders integrates the notching process, enabling space-saving and high-performance assembly. The system guides separators through minimal deflection rollers under low web tension, boosting stability and reliability. A high-performance magazine buffer ensures up to 95% system availability.

Dürr’s novel single-step filling process injects electrolyte at pressures up to 30 bar – two to three times above the industry norm – allowing for precise dosing and faster wetting of the active material, thereby shortening production times.

The joint solution is underpinned by comprehensive digitalisation. Dürr and GROB offer a full digital twin for factory simulation prior to implementation, improving planning efficiency. Real-time production control is enabled by the iTAC MES/MOM software, which includes traceability, quality analysis, and fault detection tools – all contributing to enhanced equipment effectiveness.

While dry coating takes the spotlight, Dürr continues to refine liquid coating methods. Its automated coating station and slot die system form a closed-loop control mechanism for thickness regulation, cutting scrap and start-up time. In drying, laser-based technology allows 50% faster web speeds with better energy efficiency. Post-drying calendering is performed using Dürr Ingecal machines featuring Dynamic Gap Control, which ensures ultra-precise compression using sensors accurate to 0.5 µm.

About GROB

With nearly a century of experience, GROB is a global player in the development of production lines and machine tools. Operating major plants in Germany, the US, Brazil, China, Italy, and India, the company serves top-tier automotive and industrial clients worldwide.