Dürr has installed an automatic painting line for vehicles manufacturer Nordex, which is based in Montevideo, Uruguay. This is the first automated painting line in the country.

Nordex, which has been producing vehicles in Uruguay since 1962 for different OEMs, has installed a new automatic painting line by Dürr in order to fulfil all demands in quality and precision.

To install the automatic painting line, which represents a milestone for the local industry, Nordex Uruguay has contracted Dürr Brazil. As this is the first automated painting line in the country, it was also supported by governmental and municipal agencies.

Start of production is planned to be in May 2021. The Dürr team managed the project successfully despite all challenges due to the Covid-19 pandemic.

Due to the Covid-19 pandemic the installation of the painting line was even more challenging. However, Dürr followed all safety and prevention protocols to meet Nordex’ requirements and assembled this important line in time.

“This project was challenging, mainly due to the pandemic. All areas of the company were involved, we worked together overcoming all obstacles, not only technical, but also with the permits to enter the country, due to all additional restrictions imposed by the pandemic. The process has been enriching and we have a very committed team doing work with extreme quality and efficiency. We are very happy to be part of this very important project for Nordex,” commented Guilherme Custódio, Dürr project manager.

The coating process

Dürr’s automatic painting line starts after pre-treatment of the car bodies, which prepares the body thoroughly, ensuring that the vehicle enters the line without any impurities.

After this initial step, the inner car body is painted manually, according to the customer’s requirements, using Dürr’s EcoGun spray guns.

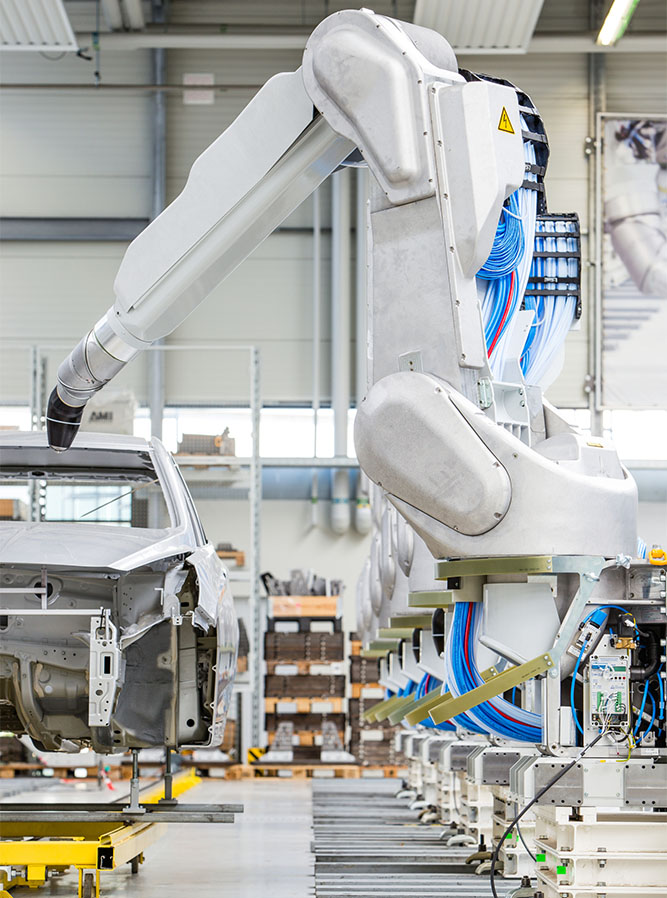

Subsequently, the exterior is painted automatically by four Dürr painting robots EcoRP, which can identify each body and configure the coating parameters accordingly.

The painting process, in which different coatings can be applied, is followed by a flash-off

period and the clear coat application to protect the coating and brightening the colour. Again, the interior is painted manually, and the exterior is painted by two Dürr EcoRP robots. In the paint supply room, eight groups of tanks – six base coats, one clear coat and one solvent – automatically provide the corresponding materials for manual as well as for automated application.

While the vehicles are being transported to the oven, there is another flash-off period. The oven has a size of 36 meters and a temperature of about 180 degrees. Finally, the vehicles pass through a cooling tunnel to lower the temperature.

A heat exchanger

controls the processing temperature at any time and guarantees optimal results.

Sustainability at the forefront

In addition to the application system, Dürr provided a Wet Scrubber System. This consists of a closed water circuit, installed below the application booth, that captures surplus paint. The contaminated water goes through a separation and filtration system, where the paint is chemically separated from the water to be used again in the process.