Solvent-free, cost-efficient solution achieves UL 94 V-0 rating, offering robust PCB protection.

Henkel has announced the commercial launch of Loctite Stycast UV 7998, the latest addition to its award-winning conformal coating range. Combining sustainability, UL 94 V-0 certification, and cost-effectiveness, the new material meets the growing demand for reliable electronics protection at a competitive price-performance ratio. Applications include home appliances, lighting, consumer electronics, and automotive sectors.

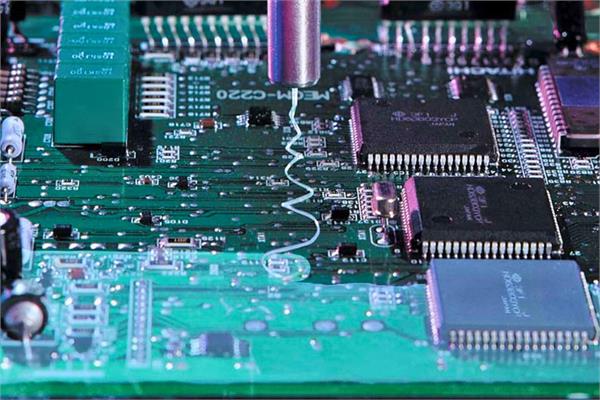

Conformal coatings are thin polymer layers applied to PCBs and components to protect against moisture, dust, chemicals, and other environmental factors that can compromise performance and lifespan. Loctite Stycast UV 7998 delivers this critical protection while enhancing safety, health, and environmental performance thanks to its solvent-free formulation.

“Meeting the demands of energy efficiency, mass production, operator safety, cost, and performance while fulfilling challenging certification standards is a difficult balance to strike. The aim was to engineer a next-generation conformal coating that delivers best-in-class performance, meets the highest sustainability criteria, and optimises process efficiency. Loctite Stycast UV 7998 has achieved these objectives, bringing the electronics market a conformal coating solution that instils product protection confidence and demonstrates Henkel’s purpose-driven innovation,” has said Oliver Steinbach, Henkel Global Innovation Project Manager.

On the processability and performance front, Loctite Stycast UV 7998 excels. The material is easy to apply, self-levels across PCB assemblies, wets evenly, and provides uniform coverage with no voiding. Once applied, curing occurs in seconds under energy-efficient UV light, followed by a secondary moisture cure, after which the PCB is fully protected from harsh environments and contaminants.

The coating’s sustainability benefits are substantial. Electronics manufacturers can reduce CO2 emissions by up to 40% compared with solvent-based alternatives, while operator health and cost efficiency are improved. VOC-free and solvent-free, Loctite Stycast UV 7998 also requires up to four times less sprayed volume to achieve the same thickness as conventional coatings. Additionally, it is tin-free, halogen-free, BPA-free, and fully RoHS- and REACH-compliant.

“In the home appliance sector, where reliability, longevity, and warranty protection are critical, we already have tremendous application success. This product was designed as a mass market solution for mainstream electronics, complementing our existing conformal coating portfolio and filling a gap not currently satisfied by other materials. Its early adoption suggests that Loctite Stycast UV 7998 has hit the target,” has added Oliver Steinbach.