According to recent market analyses, the off-road vehicle segment, driven by growth in the agricultural and infrastructure sectors, is expected to expand at a compound annual growth rate (CAGR) of over 5% in the period 2024-2029. The market of coated components for this industry, including windscreen wipers, reflects this trend, with a growing focus on sustainability and production efficiency. DOGA (Abrera, Barcelona, Spain), one of Europe’s leading manufacturers of windscreen wiper systems for off-road vehicles, recently collaborated with Cabycal (Valencia, Spain) to install a highly automated and digitalised coating line applying water-based paint.

How much attention do we pay to windscreen wipers when driving a car? We even often put off replacing them because they seem superfluous, an extra detail that cannot affect our ability to get from A to B even when not working perfectly. Often considered secondary accessories, however, windscreen wipers play a crucial role in the operational efficiency of a vehicle: they ensure safety and driving comfort by removing rain, snow, dirt, and other obstacles from the windscreen, guaranteeing optimal visibility in all weather conditions.

This also applies to windscreen wipers on off-road vehicles, such as bulldozers and tractors, and road transport vehicles, such as buses, trains, and lorries. In fact, every component of these vehicles must meet extremely stringent technical requirements, including those that seem most trivial – like windscreen wipers. They are also coated, and their finish is not just a matter of aesthetics but a vital protective barrier against corrosion, atmospheric agents, and mechanical wear (e.g. stone chips). It must guarantee high chemical resistance, film adhesion, and durability, even in environments with high dust, mud, or salinity levels. Indeed, inadequate coating can quickly compromise the functionality of windscreen wipers, increasing maintenance costs and reducing safety.

The most commonly used systems include high-performance liquid paints and powder coatings selected according to specific manufacturer requirements and the vehicle’s intended operating environment, although with a clear preference for low-VOC or water-based liquid products to reflect the industry’s growing focus on more sustainable solutions that comply with international environmental regulations. The new, digitalised, highly automated coating plant of DOGA, a company active in the production of windscreen wiper systems (motor, transmission, arm, and blade) for off-road vehicles since 1958, came into operation in mid-2024. Designed and installed by Cabycal, this line treats an average of 6,000 wiper arms per hour with a two-coat water-based primer + top coat system, requiring minimal human intervention and ensuring finishing and functionality results that perfectly comply with the strict automotive specifications that DOGA must meet.

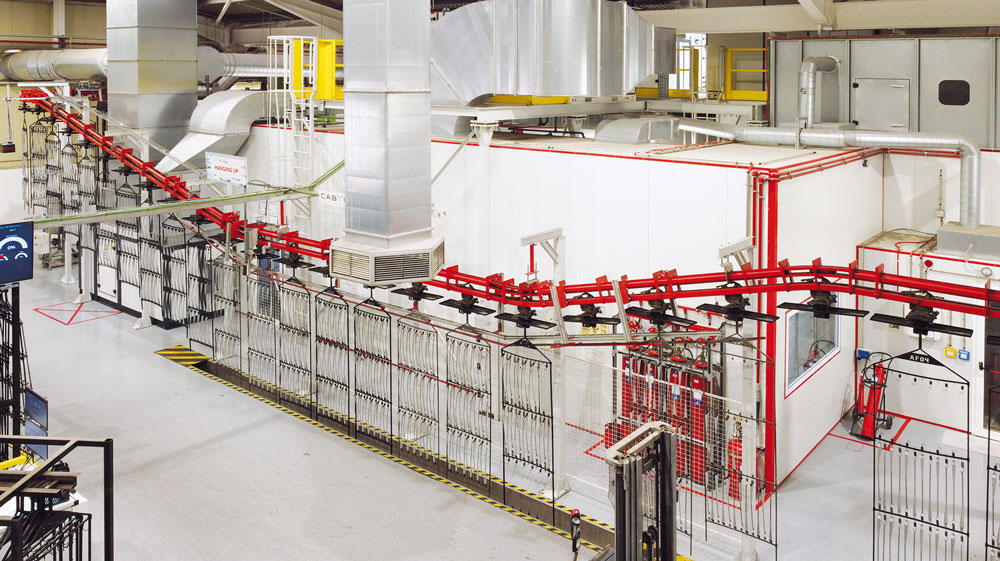

Overview of the Cabycal coating plant, a successful project despite the limited space available for installing such a highly automated line. ©Cabycal

Overview of the Cabycal coating plant, a successful project despite the limited space available for installing such a highly automated line. ©CabycalDOGA: the quality of 60 years of experience as an OEM manufacturer of windscreen wiper systems

DOGA was founded in Barcelona (Spain) in 1958, initially producing windscreen washer kits before expanding into the production of DC motors for motor vehicles and the general industry. In 1969, it moved into its first 2,300 m²-wide premises in Abrera, north of the Catalan capital: at the time, the industrial area that stands today did not yet exist, and vineyards and peach trees surrounded the factories. In 1977, the buildings constructed eight years earlier were expanded with two new halls, for a total available area of 7,100 m². In 1990, DOGA added another 5,050 m² for a moulding and welding line. The new century marked the beginning of an internationalisation path, with the opening of Doga Brasil in 2001, Doga USA in 2003, Doga Italy in 2004, Doga Nantong in 2007, Doga India and Doga Mexico in 2016, Doga Morocco in 2019, and Doga Japan in 2024.

Today, with 10 locations, a presence in 70 countries, and a staff of 1,200 people, DOGA boasts extensive know-how in developing and producing automotive components specifically designed for OEM applications. Each project is tackled in a customised manner, assigning a dedicated management team to achieve maximum performance. “Our team of engineers also acts as a technology partner to achieve results designed and tailored to specific requirements. Our ability to offer the best solution regardless of the complexity of the project is the result of our dedication and experience gained throughout a long history in the automotive industry, as well as our Technical Centre, which has a staff of 60 people who actively collaborate with customers – typically OEMs in the sectors mentioned above – to adapt and tailor our products to their needs. We specialise in the niche market of small and medium series, typically for off-road vehicles. Consequently, we handle over 1,500 different product types,” explains Raquel Gutiérrez, DOGA’s Operations Manager.

“Currently, we are leveraging the expertise we have acquired in the windscreen wiper sector to develop a new product line, namely electric motors for other applications, through our Drive Systems division,” continues Gutiérrez. “At our Abrera site, production is vertically integrated: we manufacture everything from the motor to the transmission, arm, and blade of each windscreen wiper system. In addition to the machining areas, we have several assembly and transformation lines, as well as a coating department applying water-based paint products on arms, blades, and other small windscreen wiper components.”

Coating: automotive-standard aesthetics and functionality

“An arm that washes the windscreen wiper of an agricultural tractor or construction machine is subjected to very harsh operating conditions, which pose much more stringent mechanical, chemical, and corrosion resistance coating requirements than those of car windscreen wipers,” explains Technical Project Manager Alfonso Maldonado. “Moreover, the approval and validation times for the coating systems used are very long and require numerous tests: in addition to having a specific colour and gloss degree as established by each OEM, our parts must pass rigorous tests for hardness, stone chip resistance, humidity chamber resistance, and UV resistance. Together, these requirements formed the specifications we submitted to Cabycal for our coating plant.”

Load bars entering the 9-stage spray pre-treatment tunnel with a Chemetall Oxsilan nanotechnology conversion phase. ©ipcm

Load bars entering the 9-stage spray pre-treatment tunnel with a Chemetall Oxsilan nanotechnology conversion phase. ©ipcm“After loading, the parts undergo a pre-treatment cycle including 9 stages + 2 optional sub-stages: 2 degreasing phases, 3 rinses with osmotised water, 1 surface conversion phase, and 3 final rinses. Pre-treatment is followed by blow-off, oven drying, cooling, electrostatic application of the water-based primer, flash-off, baking, cooling, electrostatic application of the water-based top coat, further flash-off, final baking, and unloading,” illustrates Aiman Alhafi, Painting Plant Manager at DOGA. “We only apply one colour, a shade of black formulated by PPG for DOGA. The primer and top coat application booths have an air recirculation system and a dedicated mixing room with safety devices for electrostatic application.”

Project requirements, strengths, and challenges

When designing the coating line for DOGA, Cabycal had to overcome a series of significant technical challenges to meet both the customer’s quality and carbon footprint reduction requirements and to cope with the limitations imposed by the installation schedule and space availability, which can be summarised as follows:

- Limited available surface area and height;

- State-of-the-art, energy-efficient technological devices in the pre-treatment process;

- Air conditioning of the air flows in the evaporators and application booths, through direct expansion with very high energy efficiency;

- Polymerisation and drying ovens with future plans for partial (hybridisation) or total electrification;

- Oven burners with modulating control and connected to the FIFO process to minimise gas consumption;

- Waste water treatment system;

- Use of water-based paints;

- Real-time communication with the production management system to automatically configure the process required by each load bar and ensure optimal, efficient, and high-quality production;

- Continuous-flow air conditioning (24/7/365) of the mixing rooms and buffer zones to achieve the highest quality standards.

The area with the two air-conditioned coating booths and their related paint rooms and flash-off stations. ©ipcm

The area with the two air-conditioned coating booths and their related paint rooms and flash-off stations. ©ipcm“The one installed at DOGA’s premises is one of the few coating lines in Spain that can boast such a high level of technology,” states Gianpiero Fontana from Cabycal. “Users generally opt for systems that are easier to maintain, even if they are not particularly efficient. DOGA, however, chose the most efficient and automated solution available. From a design perspective, Cabycal especially made a significant effort to reduce electricity consumption. Usually, in a liquid coating line, the highest operating cost is for air conditioning, i.e. to ensure constant humidity and temperature conditions during paint application. DOGA opted for the most energy-efficient option, which is direct expansion. All motors in the system are equipped with frequency inverters.

“In addition, the company invested in being ready for the future, i.e. for the possible partial or complete electrification of the drying and baking ovens, taking into account not only operating costs but also the fluctuations in raw material supply costs seen in recent years. Another critical aspect was process automation, to the point that the operator is only required to perform a few steps, while coating quality is ensured by all the automatic systems that Cabycal has installed on the line. To give a concrete idea of the design effort involved: in a space of 60 x 20 m, we laid over 8 km of electrical sheathing to install all the sensors necessary for telemetry and process digitalisation.”

Inside one of the two coating booths with a dry filtration system. The application operation is robotised. ©ipcm

Inside one of the two coating booths with a dry filtration system. The application operation is robotised. ©ipcm The control panel of one of the coating booths. ©ipcm

The control panel of one of the coating booths. ©ipcm“The biggest challenge was fitting a line with all these characteristics into the available space, which was very limited,” adds Emilio Ferrando from Cabycal. “It was not easy at all: from design to assembly, this line broke all the project standards we had maintained at Cabycal up to that point. The project also changed as it progressed because new requirements were constantly arising. For example, during construction, we had to balance the size of the loading and unloading areas because the former was too small and cramped compared to the latter. Again, in doing so, we had to deal with the structural limitations of the hall selected by DOGA for the installation of the coating line. For this reason, I can also say we learned a lot from this project, as it made us see things differently and step off the beaten track to create something new. And the undoubted result achieved by Cabycal has made us realise that we are capable of meeting even the most extreme demands of our users. When tackling projects like these, it is essential to know how to make decisions when necessary: the perfect project is one with endless planning – but no company has endless time to devote to a project. In fact, with DOGA, start-up times were another vital requirement for the new line.”

“The time available was very limited,” confirms Raquel Gutierrez from DOGA, “as were the validation times for the new water-based finishing system by our customers, close to three months. If we had not submitted the first coated parts to these tests on time, we would have had to backtrack, with obvious negative consequences for our company.”

One of the two paint rooms. Both the primer and the black top coat used by DOGA are water-based. ©ipcm

One of the two paint rooms. Both the primer and the black top coat used by DOGA are water-based. ©ipcmCustomisation, adaptation, teamwork, and expertise centralisation

“Without a doubt, designing our new coating line was a major challenge due to the need to integrate various elements and suppliers within the same project,” emphasises Raquel Gutierrez. “Cabycal was the main supplier, but there were also the paint and application equipment suppliers, each with its own requirements. DOGA’s team tried to coordinate and adapt to them all, and Cabycal was also very active in this regard.”

“Projects like this demand a lot from the people involved because they put everyone under pressure, and the customer transfers this pressure to the plant engineering team. But this is a battle you cannot lose if you are to remain clear-headed. Therefore, Cabycal has also done a great teamwork job on a daily basis to adapt to the various changes along the way,” says Emilio Ferrando.

“One of Cabycal’s strengths is undoubtedly its ability to tailor projects to each customer’s needs,” confirms Mónica Peris from Cabycal. “Every project is a challenge for us in terms of customisation, since every aspect has to be tailored to a thousand different factors, from civil engineering work to the space available, access, and so on... Our job is certainly quite varied!”

Top view of the drying and baking ovens. ©Cabycal

Top view of the drying and baking ovens. ©Cabycal Technical plan of the coating line with the booths’ air treatment and recirculation units. ©ipcm

Technical plan of the coating line with the booths’ air treatment and recirculation units. ©ipcm“The installation was very complicated both in terms of timing and execution,” - comments Alfonso Maldonado from DOGA – “as in addition to setting up the paint line, DOGA was undergoing a complete overhaul of the facilities we occupied and the processes we performed. This forced both us and Cabycal to work side by side, a collaboration that experienced moments of great tension, but thanks to the support of Gianpiero Fontana and his entire team, along with our cooperation, we managed to achieve the desired goal”.

“The person who won me over at Cabycal was Gianpiero Fontana. I immediately felt he was someone I could trust because he is analytical, pragmatic, honest. He has a very clear idea of what is possible and what is not, but he is also open to tackling challenges and trying new things. The project was expected to be very long and complex, so establishing good communication with Cabycal right from the start was essential,” says Raquel Gutierrez.

“I am proud to say that not all coating plant manufacturers in Spain are capable of completing projects of this calibre,” concludes Gianpiero Fontana from Cabycal. “If this were not the case, we could certainly not serve the automotive industry.”

From left to right: Aiman Alhafi, Alfons Maldonado, and Raquel Gutiérrez from DOGA with Gianpiero Fontana, Mónica Peris, Emilio Ferrando, and Jorge Robles from Cabycal. ©ipcm

From left to right: Aiman Alhafi, Alfons Maldonado, and Raquel Gutiérrez from DOGA with Gianpiero Fontana, Mónica Peris, Emilio Ferrando, and Jorge Robles from Cabycal. ©ipcm Other windscreen wiper components in the loading station of DOGA’s coating line. ©ipcm

Other windscreen wiper components in the loading station of DOGA’s coating line. ©ipcm