Designed with a compact footprint, Dürr’s EcoProWet EC is ideal for small to medium production volumes of up to 30 units/hour, offering a space-saving and scalable alternative to traditional continuous coating lines.

The international engineering company Dürr has expanded its innovative EcoProWet pretreatment system by adding a new cathodic electrocoating (EC) module, enhancing its modular solution for automotive painting processes.

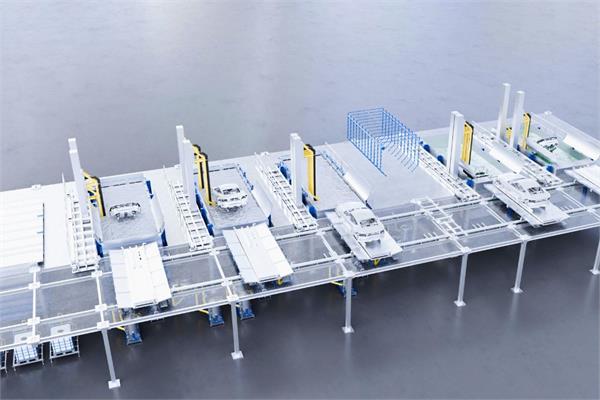

Pretreatment remains one of the most space-intensive stages in automotive painting, largely due to the large immersion tanks needed to accommodate full car bodies and lengthy process times. Dürr initially addressed this challenge with the EcoProWet PT pretreatment system, which introduced a modular and flexible approach. With the addition of EcoProWet EC, the system now covers both pretreatment and cathodic electrocoating within the same compact and adaptable platform.

The cathodic electrocoating process ensures a seamless primer layer is applied to all body surfaces, delivering essential corrosion protection and forming a strong base for subsequent paint layers. EcoProWet EC stands out from conventional PT/EC systems as the only fully scalable solution currently available, setting new benchmarks for sustainability, space efficiency, and investment costs.

Moreover, EcoProWet EC uses separate, compact basins rather than large tanks. Two independently operated pendulum towers transfer car bodies from the roller conveyor into the electrocoating bath at immersion angles of up to 60 degrees—thus allowing for customisation based on vehicle model. Each tank can handle up to 10 units/hour, with the electrocoating process taking between three and five minutes.

Thanks to its modular architecture, EcoProWet can be expanded in stages, from an initial capacity of 7.5 units/hour up to 30/hour, without disrupting ongoing operations. This flexibility enables manufacturers to adapt the system in line with evolving production needs, while simultaneously reducing paint and energy consumption. Its compact design also allows for a more efficient layout within paint shops, further minimising space requirements and operational costs.