Figros, a manufacturer of metal accessories for the fashion industry, has been working with Rösler Italiana for years to optimise its vibratory roughing and finishing processes. Thanks to state-of-the-art equipment and a closed-loop water recovery system, the company has successfully combined production efficiency with environmental sustainability in a sector that is still largely uninterested in these objectives.

The surfaces of components produced in large industrial volumes often fail to fully meet the functional and aesthetic requirements of end users, particularly in demanding sectors such as fashion item and accessory production. That is why they must be subjected to specific finishing or treatment operations aimed at improving their aesthetic, technical, and performance characteristics.

Through dedicated technologies, these processes enhance the wear and corrosion resistance of components, extend their service life, improve their appearance, and optimise their functionality by reducing friction or enhancing coating adhesion, among other benefits. These results are achieved through carefully defined treatment methods that consistently guarantee high finishing quality without compromising dimensional tolerances and the original geometry of workpieces, regardless of their complexity.

Among the most common mass finishing processes, vibratory finishing is widely used to clean, deburr, and polish metal accessories for the fashion, jewellery, accessory, and design sectors. This process involves placing the parts inside a vibrating machine, along with abrasive media and chemical compounds, to generate a combined action of friction and impact that produces a uniform, shiny surface finish on a large number of components simultaneously.

The finishing of components for fashion accessories

Despite a structural slowdown in the fashion industry, demand for increasingly higher-performance finishes is growing, thanks in part to companies in the supply chain with an innovative and forward-looking vision. Among these is Figros Srl (Barberino di Mugello, Florence), located in Tuscany, one of the Italian regions with the highest concentration of fashion districts, encompassing textiles, leather goods, and footwear.

“Figros’ history is closely intertwined with that of fashion, with over 40 years of experience in the production of metal accessories and components for the creations of the biggest international brands,” says CEO Franco Barducci. “We also place the same efficiency, precision, and production capacity at the service of other sectors, such as automotive, interior design, and general industry, which find us to be a reliable and responsive partner in terms of both design and delivery times. We can produce customised moulds and start new production runs in just three weeks.”

Figros has recently restructured its organisation and invested in a new factory with a clear vision of sustainability, a goal that is generally still neglected in the fashion industry. “In a traditionally conservative sector, the first signs of recovery can only be consolidated through a real push towards sustainability and the creation of circular business models based on recycled materials, supply chain traceability, and low-environmental impact production processes. This approach is increasingly demanded by consumers and supported by European regulations, and it is establishing itself as a key competitive factor.”

The choice of the most efficient and innovative plant solutions, therefore, enables these pioneering companies to confirm their position as leaders in the sector. “Figros produces die-cast zinc alloys and hot-forged copper and aluminium alloys. The latter process, in particular, produces rough edges and sharp corners that must be eliminated with various methods, such as vibratory roughing and vibratory finishing. We carefully select the most suitable type of treatment to obtain components that meet the expectations of our most demanding customers. To ensure near-perfect results, we have been collaborating for years with the Italian division of Rösler Oberflächentechnik GmbH, one of the world’s leading manufacturers of equipment, consumables, and services related to mass finishing and shot blasting technologies for a wide range of industries. Its Italian team assists us in selecting the most suitable plants and abrasives, as well as determining the optimal cycle times and methods to eliminate any defects generated by our processes, such as burrs, among others.”

Figros: an industrial approach anticipating change

Since 1978, Figros has been manufacturing fashion accessories and metal components for the design and general industry sectors through die-casting and hot forging. Founded by three brothers as a small artisanal business, it soon expanded due to the success of its products, moving to larger and larger facilities until it reached its current 13,000-m² factory in Barberino di Mugello, which meets the most modern energy sustainability requirements thanks to a 500-kW photovoltaic system and a commitment to purchase electricity only from renewable sources.

After 40 years of steady growth, 2018 marked a significant turning point for Figros, which became part of AMF Group, an Italian conglomerate aiming for complete control of the supply chain in the luxury manufacturing and high-tech industries. AMF Group brings together seven companies, each a leader in its own field of specialisation. In addition to Figros, it includes Mimest, dedicated to the production of semi-finished products using MIM and 3D printing technologies; Made Black, specialising in coating and PVD treatments and already the subject of an article published in ipcm® in 2020; AMF/Necessories, active in the production of finished accessories for the fashion and luxury sectors; Italcatene and Chaines et Cie, both specialising in the manufacture of rope chains, gold medals, goldsmithing products, and jewellery; and Benelli Ademaro (Scandicci, Florence), the latest company to be acquired, producing metal components.

“Currently, fashion accessories account for around 70% of our core business,” explains Barducci. “As for the remaining 30%, we also offer excellent services to the automotive, nautical, and design sectors, particularly in the field of lighting technology.”

Two processes with a long tradition

Figros specialises in two key technologies: the hot-chamber die-casting of Zamak and hot forging. The former, one of the most widely used methods for producing metal components, combines technical versatility and economic efficiency. In this company, it is carried out using 11 new-generation automated lines with clamping forces ranging from 20 to 250 tonnes. “This technology consists of melting a metal and injecting it at high pressure into the cavity of a custom-designed metal mould,” illustrates Barducci. “It is particularly suitable for zinc alloys such as Zamak, as their low melting temperature (around 400 °C) allows for fast, energy-efficient production cycles.”

Hot forging, on the other hand, is an evolution of traditional forging operations, involving the deformation of heated metal by pressing it between two shaped dies, which ensures excellent aesthetic results and superior mechanical properties. This process, widely used for brass and aluminium accessories for fashion and industry, is followed by cold shearing. Figros carries out both these activities in a dedicated department equipped with over 20 automatic presses.

It also designs and manufactures its own moulds and dies in-house, selecting the most suitable materials and technologies tailored to each customer’s specifications. “We can supply both raw and semi-finished parts thanks to our CNC machining, drilling, threading, sandblasting, and vibratory finishing departments, as well as finished components that are surface-treated by us or other companies in the AMF group.” One of the aspects that has made Figros a benchmark in this highly competitive sector is its technical consulting activity, which sees it working alongside customers from the early stages of project development to streamline processes and optimise time and costs.

Figros uses 11 new-generation automated lines for the hot-chamber die-casting of Zamak. Ⓒ Figros

Figros uses 11 new-generation automated lines for the hot-chamber die-casting of Zamak. Ⓒ Figros The hot forging department for copper and aluminium alloys. Ⓒ Figros

The hot forging department for copper and aluminium alloys. Ⓒ FigrosTwo different treatments: vibratory roughing and vibratory finishing

As part of a standard cycle in the die-casting department, the parts are deburred and then subjected to vibratory roughing to remove any surface defects generated in the previous stages. “There are instances where this process cannot be applied and must be replaced with thermal or manual deburring,” continues Barducci. “However, in most cases, we can carry it out by choosing the most suitable abrasives, times, and removal methods with the technical support of Rösler, to eliminate any defects or residues. Vibratory finishing, on the other hand, is a subsequent operation that enables us to achieve a degree of quality and gloss that often makes more expensive processes, such as polishing, unnecessary. Indeed, although it can be partially automated, polishing largely remains a manual operation, making it more costly and less consistent. That is why we opt for vibratory finishing whenever possible.”

This department handles both hot-forged brass parts, which are the majority, and die-cast Zamak parts. “Most of our competitors use different vibratory finishing machines for each type of material, thus limiting their flexibility: when the metal changes, there is a risk of leaving a plant idle. Thanks to the systems supplied by Rösler, we have overcome this limitation, as we can use the same machine for both brass and Zamak.”

Figros utilises 14 vibratory roughing and finishing systems, as well as 2 drying machines, for the mass finishing of its components. Ⓒ ipcm

Figros utilises 14 vibratory roughing and finishing systems, as well as 2 drying machines, for the mass finishing of its components. Ⓒ ipcm Various types of circular vibrators installed by Rösler. Ⓒ ipcm

Various types of circular vibrators installed by Rösler. Ⓒ ipcmThe Rösler plant equipment

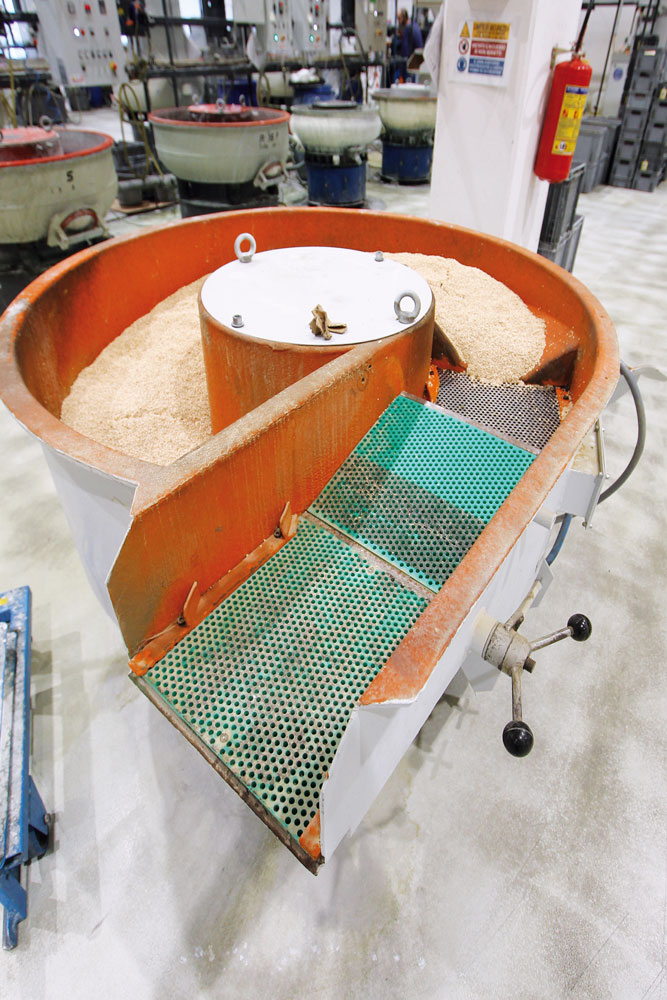

“We supplied Figros with 14 circular vibratory finishing machines from our Mini 120, STB 20, and ST14 TRH series and a TMD 11 drying system,” states Federico Milazzo, Sales Director at Rösler Italia. “Vibratory finishing machines are a versatile and straightforward solution for accomplishing multiple finishing, deburring, smoothing, and polishing tasks using plastic, ceramic, porcelain, and vegetable granules as abrasives. Their operation is simple: a special flanged electric motor equipped with unbalanced weights is mounted in the centre of the unit and causes the entire tank to vibrate. The resulting rotation generates the typical abrasive-tool mix movement, removing roughness from the surfaces of semi-finished products. Each machine can also be equipped with peripheral devices for part loading and post-treatment.” The flat-bottomed tank made of carbon steel sheet ensures optimal immersion of the workpieces. The components processed in the 4 Mini 120 machines are extracted manually, whereas the 3 ST14 TRH systems have automatic unloading equipment. Both types feature a wear-resistant polyurethane lining with a thickness of 12 to 20 mm.

All vibratory finishing operations are wet processes, and the parts must be dried before they can be fed into the following production process. “Rösler provides its customers with smart solutions that allow seamlessly and automatically connecting the drying system to the vibratory finishing one while ensuring high performance and maximum energy efficiency. At Figros, we have installed a TMD 11 drying plant for this purpose. Operating in both batch and continuous flow modes, the systems in this series feature a spiral-shaped tank ensuring that all components are unloaded.”

Surface roughness is removed from semi-finished products through a combination of circular motion and the use of specifically selected abrasives. Ⓒ ipcm

Surface roughness is removed from semi-finished products through a combination of circular motion and the use of specifically selected abrasives. Ⓒ ipcmThe water recovery system

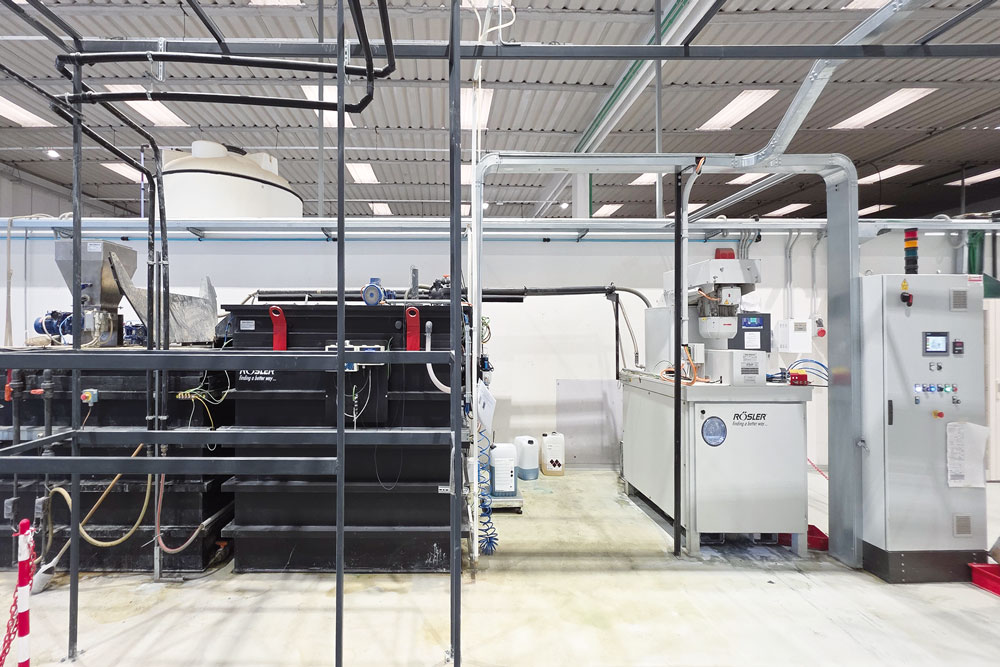

Today, almost all vibratory finishing processes can integrate a water cleaning system that performs two-phase solid-liquid separation by using centrifugal force, allowing for the recovery of waste water. “For this plant,” continues Milazzo, “we have designed a closed-loop recirculation plant that allows recovering the water used in the vibratory roughing and finishing processes for both Zamak and brass parts, avoiding any contamination between the two materials. The sludge is centrifuged and separated automatically; the recovered water is supplemented with additives and returned to the vibratory finishing systems.”

“This project was one of the highlights of our collaboration,” Barducci emphasises. “It gives us two key advantages: maximum production flexibility, as we do not have to worry about the type of material being processed, and sustainable, cost-effective water management.” For the Tuscan company, using state-of-the-art machinery is indeed a strategic choice in terms of both process quality and environmental sustainability.

The closed-loop water recovery system. Ⓒ ipcm

The closed-loop water recovery system. Ⓒ ipcm Depending on purity requirements and physical limits relating to particle size and weight, water recovery systems can achieve a flow rate of up to 6,000 litres/hour. Ⓒ ipcm

Depending on purity requirements and physical limits relating to particle size and weight, water recovery systems can achieve a flow rate of up to 6,000 litres/hour. Ⓒ ipcmChoosing the ideal abrasive

Rösler also collaborates with Figros in selecting the most suitable abrasives based on the type of material, the required finish, the workpiece loading method, and the desired results. “Our company supplies not only process equipment but also the required abrasives, carefully chosen for their characteristics and size to avoid any jamming,” explains Milazzo. Specifically, these include ceramic and plastic abrasives, as well as chemical compounds for both vibratory finishing and water treatment. For the drying machines, on the other hand, Rösler supplies corn sawdust-based products that are particularly resistant and ideal for ensuring the best results.

“We are very proud of our partnership with Figros, which has become one of our best calling cards in this particularly competitive industry,” Milazzo concludes.

The TMD 11 series drying system installed by Rösler. Ⓒ ipcm

The TMD 11 series drying system installed by Rösler. Ⓒ ipcm A carabiner clip lever after the drying stage. Ⓒ ipcm

A carabiner clip lever after the drying stage. Ⓒ ipcm Rösler also supplies the abrasives for these processes, carefully selected for their characteristics and size to prevent jamming. Ⓒ ipcm

Rösler also supplies the abrasives for these processes, carefully selected for their characteristics and size to prevent jamming. Ⓒ ipcmFigros’ commitment to driving change in the industry

Barducci adds that “Rösler is going to play a key role in one of the innovative projects we are launching: the goal is to replace, wherever possible, traditional polishing operations, which are costly and additional, with vibratory finishing processes, which are more effective in achieving the gloss degree required by customers – who, however, are not easy to convince to adopt processing methods other than those they are used to. This is another reason why the fashion world is sometimes perceived as a sector in decline, one that is reluctant to change. But at Figros, we prefer to talk about transition, because we believe that companies that manage to combine sustainability, technology, and craftsmanship will gain a real competitive advantage in the new global scenario.”

In this context, the most advanced industrial companies will undoubtedly require partners who can provide high-performance machinery, efficient processes, and sustainable solutions that meet the evolving needs of the supply chain and support technological innovation.