Chery Automobile will rely on 92 painting robots and the intelligent software from Dürr.

Dürr has been commissioned a new turnkey paint shop in Wuhu for Chery Automobile Co. Ltd., a Chinese car manufacturer that requires flexible production operations for various models and drive systems.

The company, established in 1997, is China’s top car exporter and has already sold over nine million vehicles in more than eighty countries and regions. As it needs flexibility, scalability, software expertise and high quality, it has reached out to Dürr for a highly intelligent paint shop that will coat several vehicle categories, from typical bodies to SUVs.

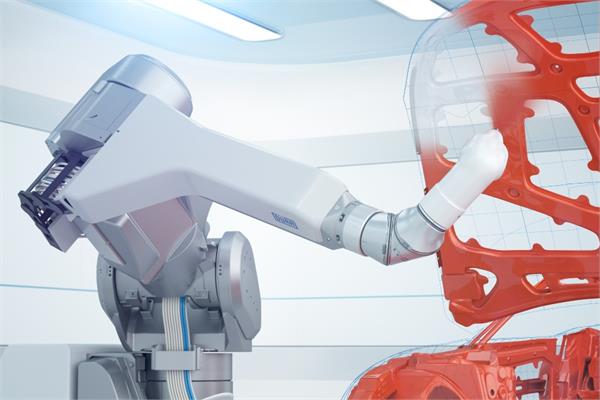

Dürr is providing 92 painting robots, including sixteen EcoRP E043i and four EcoRPL043i – with seven axes allowing to easily reach even difficult-to-access places in the body interior – equipped with EcoBellCleaner D2, which can clean the high-speed rotary atomizers from the outside within the cycle time. The colour changes and the colour channel cleaning inside the atomizer occur in parallel, so the system is ready for the next operation after fifteen seconds. In addition, there are thirty-eight EcoR30L 16i and EcoRS 16i sealing robots for the bonding and sealing processes and four compatible cleaning robots.

The German provider will also install its DXQ software products to ensure a higher-level control of the whole plant. The software tracks the life cycle of each body, the DXQequipment.operation human-machine interface monitors individual processes from any device, the DXQquality.management connects process monitoring with vehicle details, creating a seamless data record for each vehicle and the DXQequipment.maintenance logs when individual components such as pumps, valves or filters need to be maintained.

Finally, EcoSmart VEC regulates the fresh and exhaust air control of the ovens, with an intelligent air management tool that adjusts the energy supply to the actual need and reduces it in partial-load operation, saving not only energy but reducing also CO2

emissions. The paint shop is designed to allow future expansion and can also handle two-tone painting. The plant will be ready for operation within eight months and will then complete bodies at a rate of up to 60/hour.