Automation, machine vision, and artificial intelligence are redefining surface quality inspection in the automotive paint process.

Tunnel for automatic defect detection

Tunnel for automatic defect detectionThe quality of a vehicle’s surface finish not only determines its aesthetic appeal—it also influences overall product perception, customer loyalty, and brand reputation. For this reason, quality control in the paint process is one of the most critical challenges in automotive manufacturing plants. Despite technological advances, many factories still rely on manual visual inspections, which are subject to variability, fatigue, and a lack of traceability. In this context, automated inspection using machine vision has emerged as a robust, objective, and scalable solution. We spoke with Javier Aramendi, Chief Commercial Officer at EINES Vision Systems, to learn how automated paint inspection is transforming quality standards in the automotive industry.

Paint inspection: one of the final barriers to full digitalization

Why does paint inspection remain such a complex challenge in a highly automated environment like the automotive industry?

Paint is a complex, dynamic surface. It reflects light, colour, and texture, and even the slightest imperfection, such as a dust particle, crater, or flow mark, can disrupt its appearance. Detecting these types of defects objectively and consistently, regardless of lighting conditions or operator experience, is a major technical challenge. And the cost of an undetected defect reaching the final customer goes far beyond economics: it directly impacts brand image.

Data-driven technology, not perceptions

What does machine vision offer compared to traditional manual inspection?

Fundamentally: objectivity, traceability, and complete coverage. Our system, ESFI (EINES Surface Quality Paint Inspector), uses a setup of high-resolution cameras combined with uniform white LED lighting, capable of capturing more than 40,000 images per vehicle. From this data, vision algorithms and convolutional neural networks (CNNs) analyse how light is reflected on the painted surface to detect and classify defects in real time. In addition, multi-frame techniques allow the same defect to be analysed from different angles and moments, increasing diagnostic reliability.

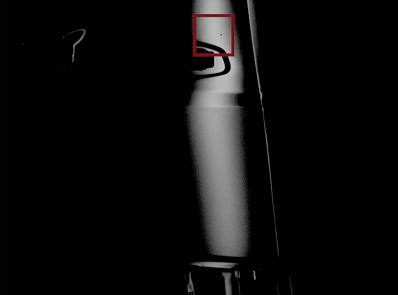

Tunnel light reflection on the painted bodywork

Tunnel light reflection on the painted bodyworkTypes of defects detected and accuracy achieved

What types of defects can the system identify and with what level of precision?

The system detects common issues such as dust, craters, drips, and orange peel, as well as hard-to-see flaws like surface dents or pinholes. Thanks to prior training of the neural networks with both real and synthetic data, classification capabilities are extremely accurate. In real production environments, audited results from our clients show a detection rate above 99% - far exceeding the 50-80% range typical of manual inspection, depending on the environment and operator experience.

Efficiency, traceability, and reduced operating costs

What operational advantages does automated inspection offer?

The benefits are numerous. First, consistency: the system delivers stable results over time, free from external influence. Second, data traceability: each detected defect is recorded with detailed information on its location, type, and size, enabling further analysis and continuous improvement. And third, integration with automatic repair systems, since defect location data can be sent directly to a robotic cell. All of this translates into fewer reworks, improved operational efficiency, and a significant reduction in the cost per inspected unit.

Finish Line screen for displaying defects

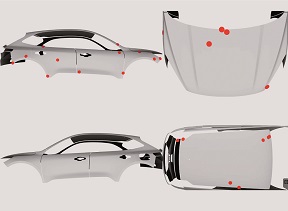

Finish Line screen for displaying defectsAgile deployment and adaptability via simulation and Digital Twin

How is the solution adapted to the specific needs of each plant or vehicle model?

During the design phase, we use a Digital Twin simulation environment that allows us to define the optimal system architecture for each model or body type. We simulate vehicle behaviour inside the tunnel, camera placement, lighting conditions, and artificial defect detection. This enables us to anticipate coverage needs, shorten commissioning times, and minimize initial investment.

A proven industrial solution, not a proof of concept

Is this a pilot-phase technology, or is it already validated in industrial settings?

It’s a fully mature solution. Since 2016, we’ve installed dozens of inspection tunnels for major automotive OEMs worldwide, with excellent results in terms of reliability, stability, and return on investment. This is not an experimental technology - it’s a proven tool in continuous evolution, with short improvement cycles thanks to production data feedback.

Control across all paint process phases

At which stages of the paint process should this type of system be installed?

It can be installed at multiple stages: after cathodic dip coating (KTL), after primer application, and especially after the topcoat. Each stage allows the detection of different types of defects, and the earlier they are identified, the easier and more cost-effective they are to fix.

Defect frame detected

Defect frame detectedImpact on customer perception and brand value

What are the benefits in terms of perceived quality and brand image?

Surface quality is one of the first aspects a customer evaluates when seeing a vehicle. A visible defect raises concerns about the overall reliability of the product. Therefore, a system that ensures finish uniformity not only enhances internal quality but also protects product image and brand reputation.

The future of quality control: from reactive to predictive

What’s the next step in this technological evolution?

The ultimate goal is to move toward predictive and preventive systems. We’re already working with models that correlate detected defects with process parameters in the paint booth, such as humidity, temperature, airflow, or robot painter behaviour. This paves the way for intelligent control systems that not only detect but also anticipate deviations and propose automatic adjustments to prevent them.

ESFI at different paint phases

ESFI at different paint phasesAutomated paint quality control is no longer optional—it’s essential for competitiveness, efficiency, and excellence. Machine vision has proven it can see what the human eye cannot—and go further, by turning data into intelligent decisions. At EINES Vision Systems, we understand that every production plant has unique characteristics: specific workflows, line configurations, and quality standards. That’s why we approach each project with a tailored mindset, thoroughly analysing the operational context and client goals.

If your organization is considering implementing automatic paint inspection systems, EINES Vision Systems

would be happy to assess your specific case and apply our expertise to identify the most suitable solution.

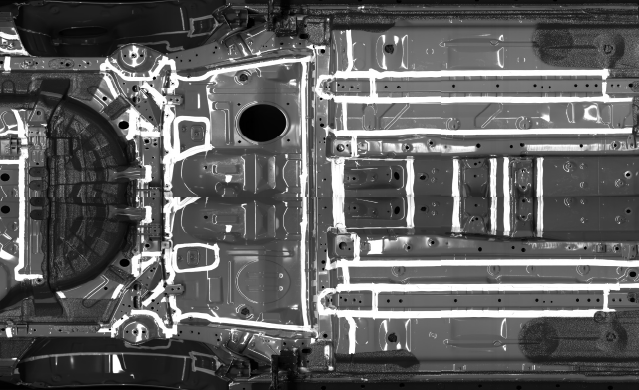

Total solution with ESFI tunnel and automatic repair cell

Total solution with ESFI tunnel and automatic repair cellOther Solutions for Paint Quality Control

Sealer check

Sealer checkVerification of the correct application of structural sealants and adhesives on car bodies, ensuring continuity, proper thickness, and the absence of gaps or excess material in critical sealing areas.

Inspection of correct application of structural sealants through advanced image analysis, detecting chromatic variations that could impact the final finish perception and panel-to-panel consistency.

EINES Vision System can study your particular case: https://eines.com/ipmc_eines/