The quick and easy solutions for electronics maintenance in corrosive environments developed by Cortec have already been successfully applied in several sectors.

ElectriCorr™ VpCI®-238 and ElectriCorr™ VpCI®-239 are two electronics cleaner and protector formulas in ready-to-use spray can format developed by Cortec® Corporation as a preventative maintenance solution for light and heavy-duty corrosion concerns.

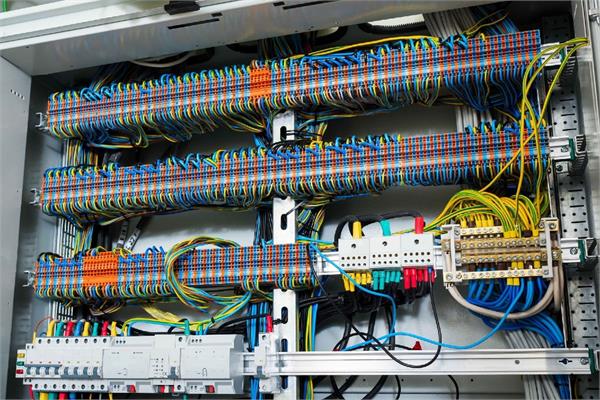

As a matter of fact, the multifunctional corrosion inhibitors can be left to dry into a non-sticky corrosion inhibiting protective film that does not change conductivity or interfere with the operation of the equipment. Furthermore, they easily allow to remove oil, grime, wax and other contaminants when employed as a penetrating cleaning solution. In addition, ElectriCorr VpCI-238 and 239 can be combined with VpCI Emitters to maximise corrosion protection inside an electrical enclosure and on open electronic panels.

ElectriCorr VpCI-238

The versatile solution developed by Cortec have several uses, as it can be applied on printed circuit boards, generators and junction boxes, as well as on electrical outlets, contacts, components and motors that need to be protected from corrosion.

ElectriCorr VpCI-238 is recommended for lighter-duty indoor applications and has already proven successful in restoring corroded circuit boards for a marine maintenance company specialised in servicing radar, sounders, plotters and other electronic components.

ElectriCorr VpCI-239

ElectriCorr VpCI-239, on the other hand, is ideal for outdoor and heavier-duty applications and has been employed as a sustainable tool in a responsible strategy for safeguarding the inside of high voltage (SRCs) from corrosion during the shipping process. In another situation, the solution was sprayed over finned tubes being prepared for overseas shipment along with VpCI packaging materials. It is also commonly used as part of an electrical layup strategy during mothballing or rig stacking in offshore and other corrosive environments.

One special application involved one municipal wastewater treatment operation that was experiencing frequent failures of expensive HMI electronics panels. Cortec managed to minimise the airflow by applying a light spray of ElectriCorr VpCI-239 after powering down the equipment and placing one Corrosorber® and one VpCI®-111 Emitter inside each panel. In doing so, the company reduced the replacement frequency and the costs, ensuring a high return on the investment.

In addition, ElectriCorr VpCI-239 is not reserved only for electricals: in 2016, it was used to protect a steam turbine rotor from flash rusting after rust removal in a coastal power plant with a high-chloride and moisture-laden environment.