Inver Press Srl has recently completed the installation of a new cataphoresis plant designed and built by Silvi Srl, integrating it into its production process to finish components for heavy-duty vehicles. The plant has enabled it to insource this crucial phase, improving quality control and speeding up operations.

The production of parts for heavy-duty vehicles, such as brake shoes and braking system components, plays a strategic role in the commercial and industrial vehicle sector, where safety, reliability, and durability are key requirements. Indeed, these components operate under extremely harsh conditions, characterised by high loads, constant pressure, and continuous exposure to atmospheric agents. Therefore, when producing parts such as oil cups, brake shoes, brake dust covers, brake pad retaining plates, flat and conical washers, and phonic wheels for ABS systems, each process phase should be aimed at achieving the best possible results and ensuring high-level performance. In this context, advanced production technologies and specific surface treatments decisively contribute to improving wear and corrosion resistance, as well as the safety of the systems for which the components are intended. The need to manufacture reliable parts that comply with regulations thus makes their production a key element for competitiveness and innovation in the heavy vehicle sector.

Inver Press (Valmadrera, Lecco, Italy) is one of the few European companies specialising precisely in this type of component. Founded in 1970, it established itself on the Italian market by manufacturing parts for the household appliance sector. In the early 2000s, it decided to diversify and specialise in the production of automotive components, with a focus on heavy goods vehicles. “Inver-press manufactures niche products designed for a very specific sector that demands high quality standards. The volumes required are low, given the high engineering complexity, but processing and delivery times are extremely fast,” says Federico Mossini, Production Manager at Inver Press. “We can safely say that we are one of the very few companies in Europe to carry out this type of work for major customers such as Cummins, Dana, and SAF Holland.”

The bars have a capacity of 500 kg. Ⓒ Silvi

The bars have a capacity of 500 kg. Ⓒ SilviThe production process

The production process starts with the raw material: steel. The first step is cold shearing, followed by deep drawing, CNC machining, robotic welding, heat treatment, and shot blasting with OMSG machines; Inver Press has a CWB 850 4/FAC tunnel shot blasting machine with a metal mesh belt and four 7.5-kW turbines and a Tappeto Rampante® shot blasting machine, model SG2 RNH, with a volumetric capacity of 150 dm3 and a maximum load of 500 kg, equipped with a 7.5-kW turbine.

The final stage of the finishing process is cataphoretic coating. “Until this year, this was outsourced to external partners. However, we recently decided to insource it for several reasons,” explains Mossini. “In our previous setup, the final coating stage was the most critical, as we had to send our parts outside our premises. This created a bottleneck, blocking production and lengthening delivery times. Moreover, high quality is of the essence when producing components for such a demanding sector, and insourcing the cataphoresis process makes it easier to control it, including by selecting the best partners. Finally, I personally find cataphoresis to be a very interesting and fascinating technology, so we approached the installation of this new plant with an open mind, working daily to improve its performance with the aim of also being able to offer a contract service.”

The Tappeto Rampante® SG2 RNH shot blasting machine, designed and installed by OMSG. Ⓒ OMSG

The Tappeto Rampante® SG2 RNH shot blasting machine, designed and installed by OMSG. Ⓒ OMSGA custom-designed system

In the automotive sector, cataphoresis is now an established standard for coating parts, required by the market to ensure durability, reliability, and compliance with leading manufacturers’ specifications. Inver Press decided to insource this process by entrusting Silvi, a plant engineering and construction company based in Peregallo (Monza e Brianza, Italy), with the design and construction of the new cataphoresis plant to be integrated into its workflow. “We have known Silvi for several years because we had already collaborated on other projects, so we felt confident in relying on them to design and build this system. We were very satisfied with our collaboration with this company and particularly with Daniele Fumagalli, its technical and commercial director, who, thanks to his experience, designed a layout that was perfectly adapted to the available space, which was limited, thus requiring functional solutions to optimise the line’s footprint.”

The line built by Silvi was installed in June 2025 and includes a closed-cell spray pre-treatment system. The parts are loaded onto bars with a capacity of 500 kg, a fundamental technical aspect considering that Inver-press handles large and heavy components such as brake shoes, which can weigh up to 6 kg each. The load bars move along a SE.PO. step-by-step monorail conveyor, enabling the parts to undergo a pre-treatment and cataphoresis cycle specially developed for Inver Press by PPG, designed to treat galvanised, ferrous, and multi-metal substrates so that they can pass cyclic corrosion resistance tests and, in particular, meet DBL and Volvo specifications. In the automotive sector, the new trends no longer require only passing the ASTM B117 corrosion test (neutral salt spray); they increasingly call for simulating extreme environmental conditions more representative of those the vehicles will be subjected to throughout their life cycle.

Inver Press’ pre-treatment cycle includes the following stages: alkaline degreasing at 50 °C; two rinses with mains water; soft pickling at a pH of 5 to treat substrates with scale, carbon residues, and oxidised galvanised materials; microcrystalline nanotechnology activation; a nickel-free phosphating phase that completes the metal conversion process, reaching a density of about 2 grams/m² of bicationic phosphate; one further rinse with mains water; one rinse with osmotic water; zirconium passivation; and a final rinse with osmotic water. The tunnel supplied by Silvi is also equipped with a continuous-flow sludge removal system using a filter press in the phosphating tank.

The closed-cell spray pre-treatment system by Silvi. Ⓒ Silvi

The closed-cell spray pre-treatment system by Silvi. Ⓒ Silvi Parts before the cataphoresis treatment: the plant is designed for a production capacity of 12 load bars per hour. Ⓒ Silvi

Parts before the cataphoresis treatment: the plant is designed for a production capacity of 12 load bars per hour. Ⓒ Silvi Parts exiting the cataphoresis tank. Ⓒ Silvi

Parts exiting the cataphoresis tank. Ⓒ SilviAfter pre-treatment, the components are transferred to the cataphoresis tank, where they are treated with products from PPG’s Powercron 10X® range, which are approved for DBL and Volvo specifications and recommended for automotive components manufactured by Tier 1 suppliers. The resulting process is a latest-generation tin-free epoxy cataphoresis treatment. “Inver-press was one of the very first companies to select this innovative system, which is unique on the Italian market, to distinguish itself as a supplier of superior technology,” notes Luca Sforzini, Commercial Director Tiers France & Italy at PPG. “In particular, P10X covers moulding burrs, shearing edges, and imperfections produced by machining operations even at low thicknesses (12-25 microns). Any OEM knows that a galvanised coating protects edges better than a simple CRS, but when only a ferrous substrate is used, a coating with high edge coverage is mandatory for long-term protection. Supported by PPG, Inver Press chose the P10X product range for its highly flexible approach to edge corrosion, enabling it to meet all its customers’ needs.”

Once the cataphoresis treatment is complete, the parts undergo double rinsing with ultrafiltrate, followed by a blow-off stage, before entering the closed-cell drying oven with air-stream heat exchangers. The cycle ends with the unloading of the parts from the load bars. The plant is designed for a production capacity of 12 load bars per hour.

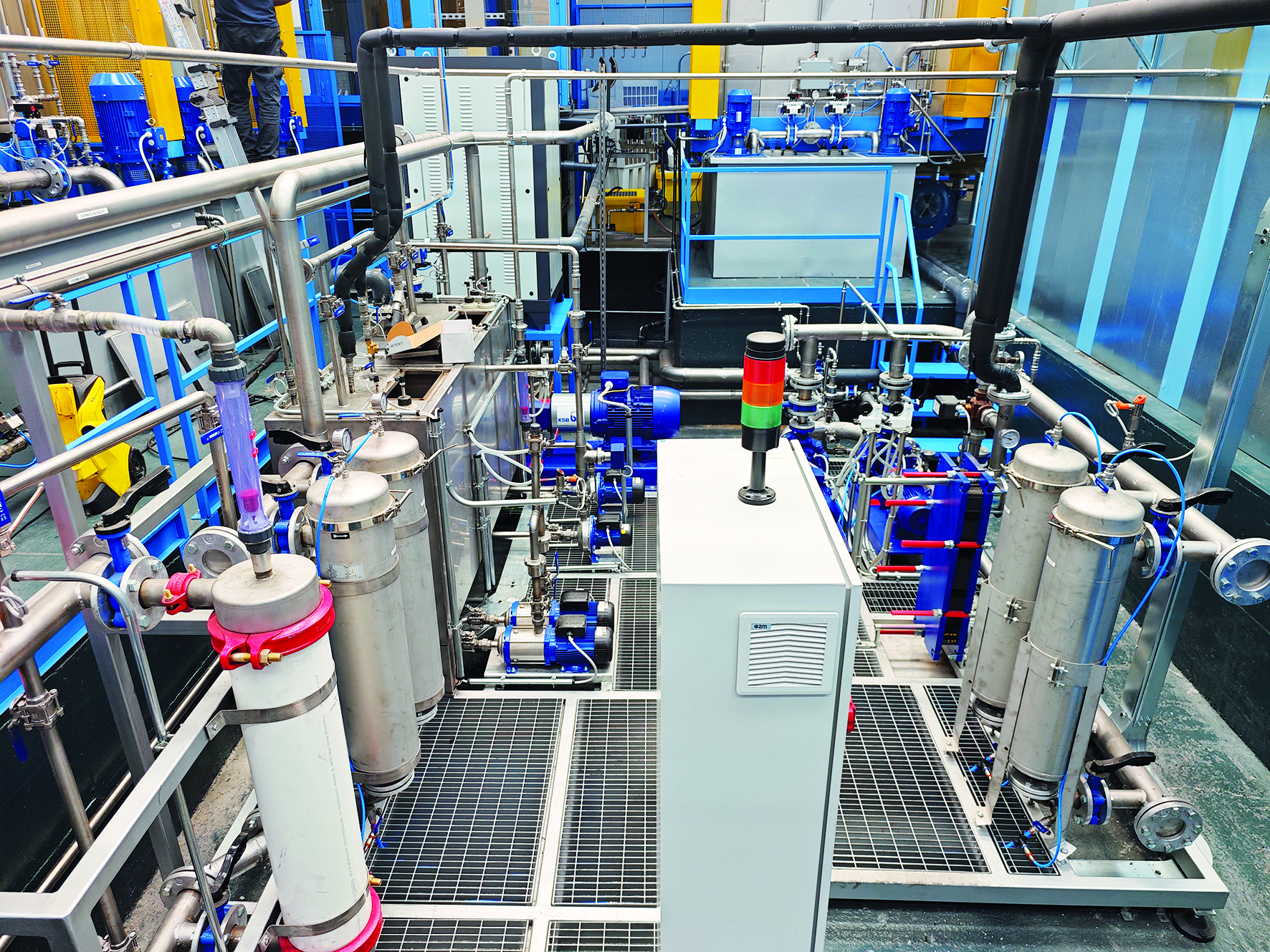

Full support and remote connection

Particular attention was paid to the design of the plant’s auxiliary devices, with the aim of ensuring high standards of safety, environmental sustainability, and process control. The integrated technologies ensure the efficient management of emissions, waste water, and chemical parameters while providing operational continuity and consistent surface treatment and cataphoresis quality. “The plant is equipped with a centralised fume extraction and abatement solution serving the pre-treatment and cataphoresis lines, consisting of polypropylene wet scrubbers,” explains Daniele Fumagalli. “There are two separate abatement systems: one is devoted to hot fumes from thermal processes and the other to cold fumes generated by chemical treatment tanks. We also installed a chemical storage and recirculation device and a waste water management system. Waste water is treated using a vacuum evaporator, which recovers up to 95% of it, enabling the plant to operate with zero discharge.”

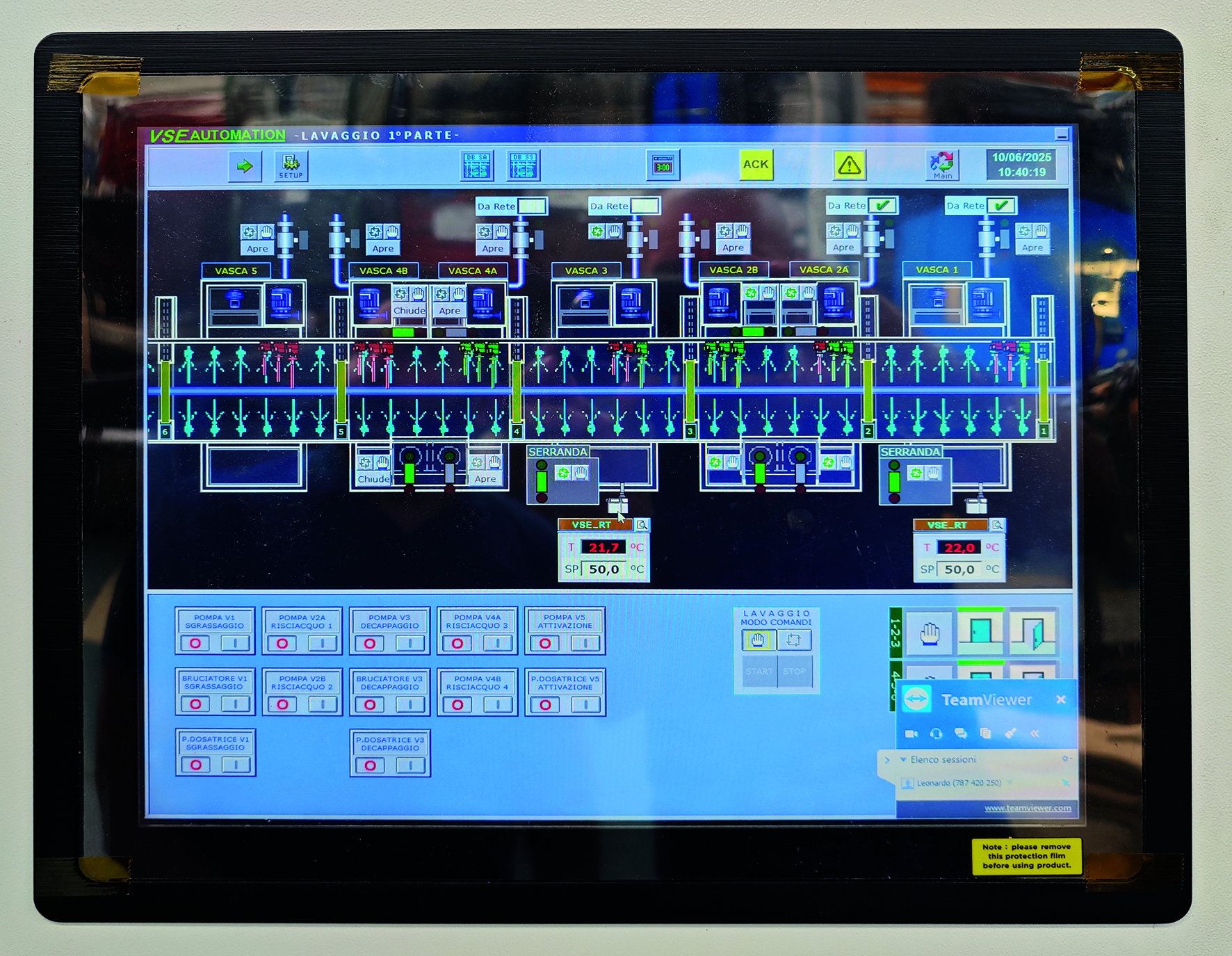

“This is a small plant, but complete and up-to-date: everything is connected remotely, and we can monitor its operation wherever we are,” indicates Mossini. The quality standards pursued by Inver Press are also reflected in the daily maintenance carried out on the pre-treatment tunnel, as well as in the implementation of an internal chemical laboratory that conducts daily tests and titrations on all tanks. “In addition, every month, we send samples to PPG for analysis: these checks have allowed us to significantly raise our quality level compared with the past,” Mossini concludes.

Pre-treatment touchscreen. Ⓒ Silvi

Pre-treatment touchscreen. Ⓒ Silvi The ultrafiltration system. Ⓒ Silvi

The ultrafiltration system. Ⓒ Silvi The drying oven. Ⓒ Silvi

The drying oven. Ⓒ SilviTechnology and control to meet market demands

By insourcing its cataphoresis operations, Inver Press took a further step in its path of growth and specialisation, strengthening control over quality, efficiency, and flexibility. The custom-designed plant supplied by Silvi, complete with advanced support systems, enables this company to respond proactively and comprehensively to the automotive sector’s needs, particularly in the field of heavy-duty vehicles. This business investment marked not only an evolution in terms of performance but also a choice geared towards continuity, reliability, and innovation, key elements for operating in a highly specialised and selective market. Now, thanks to its quality-oriented approach and continuous improvement, Inver-press aims to consolidate its role as a qualified partner for the leading manufacturers in the sector and open up new opportunities, including in the field of contract coating.

The external scrubbers. Ⓒ ipcm®

The external scrubbers. Ⓒ ipcm®